Design & Technology students must be familiar with a range of temporary and permanent joining methods for metals. This article helps students revise this information and concludes with sample examination questions from the Cambridge AS/A Level syllabus.

Temporary joining methods for metal

Nuts & Bolts

- Bolt sits in a clearance hole drilled through both parts

- Uses a washer, sometimes on both sides to spread the load and prevent damage to material when tightened

- Nut is threaded on end and tightened

Note: Screws can be used to join sheet metal to another material, such as wood, but cannot be used to screw directly into metal.

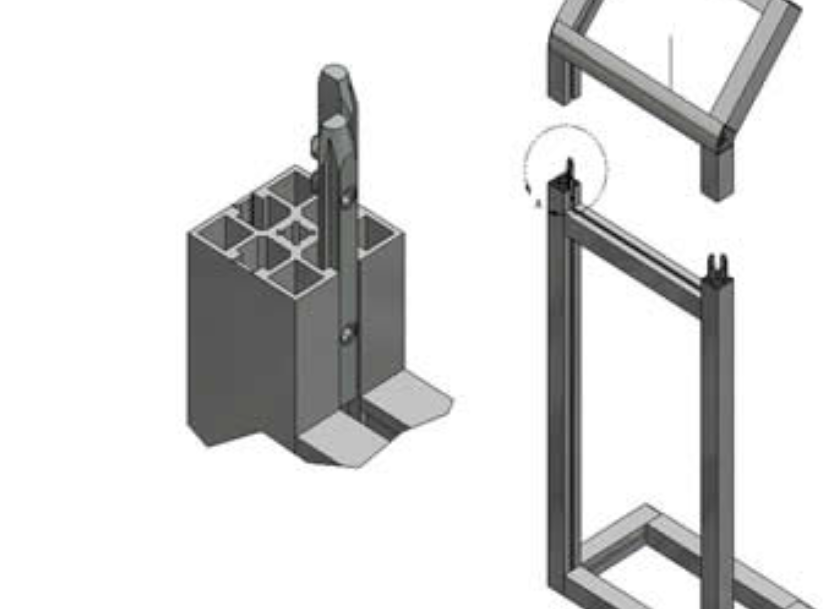

Slot-in parts

Permanent joining methods

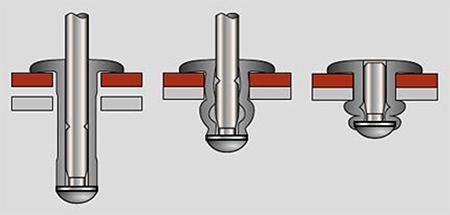

Rivets

- Typically used to join thin sheets of metal together

- Rivets are hammered to close (or put in with a rivet gun), so cannot be undone

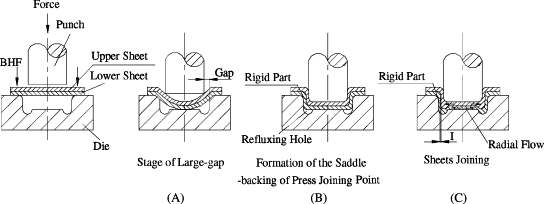

Press joining

- Metal is placed between a punch and a die, pressing the metal into an interlocked shape

- Not as secure as riveting

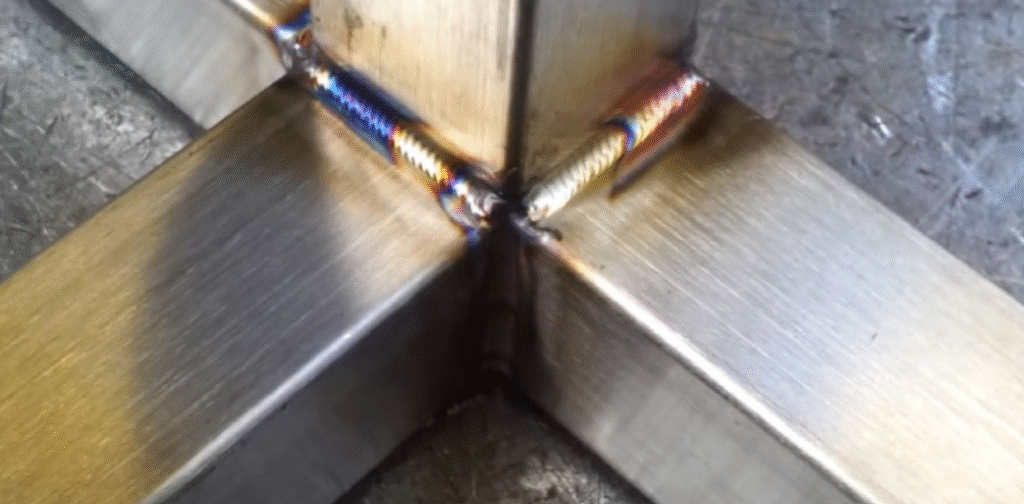

Welding

- Melts and fuses edges of metal together, typically using high heat

- Creates a strong permanent bond

- Common types include arc welding (using electrical current), gas welding (using flame), and newer techniques like laser welding

- Sometimes uses a separate metal rod or wire that acts as a filler materials to melt and add to the joint (the filler is usually the same material as the item being welded)

- Different metals are sometimes hard to weld together and some are impossible

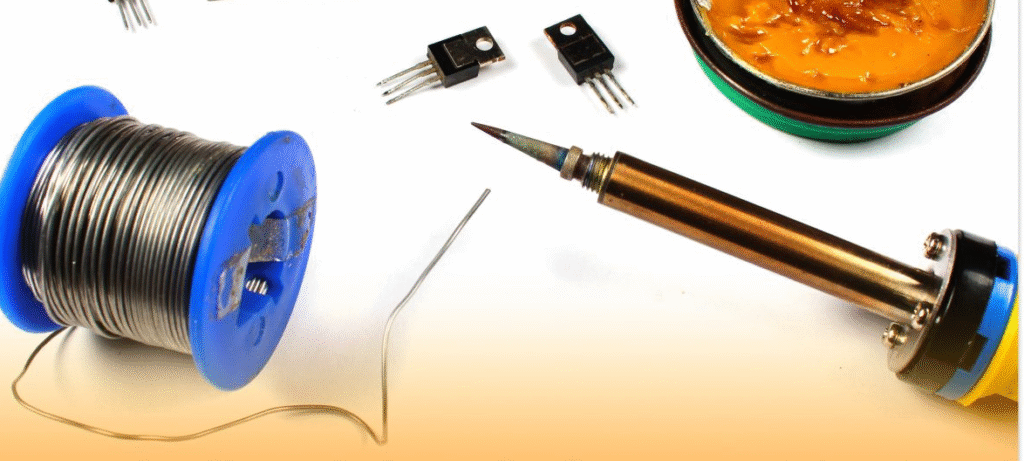

Soldering

- For light use applications (much weaker than welding)

- Commonly used to join circuit wires together using a soldering iron

- A filler rod made from low-melt-point metal called “solder” (often made from tin or silver alloys) is melted and used to connect two pieces, without melting the materials that are joined themselves

- The molten solder flows between the joint surfaces and hardens when cooled, creating a mechanical and electrical connection.

- Requires clean surfaces and often needs “flux” – a chemical to remove oxidation/rust/tarnish (although this can be built in to the solder)

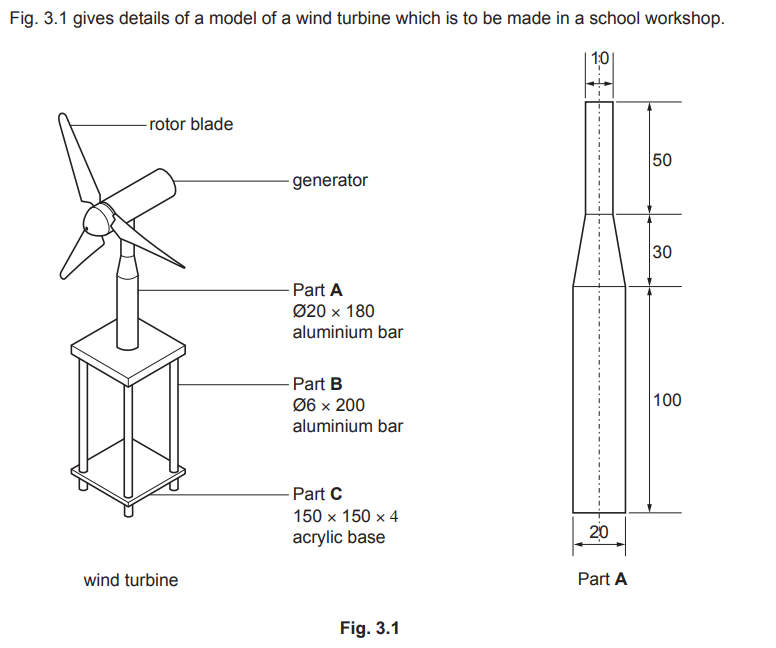

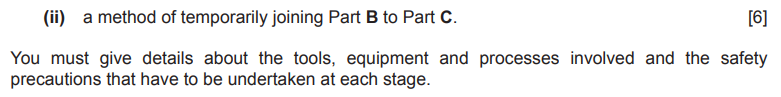

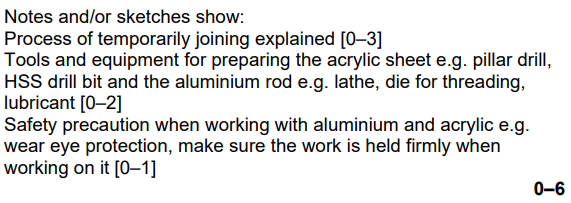

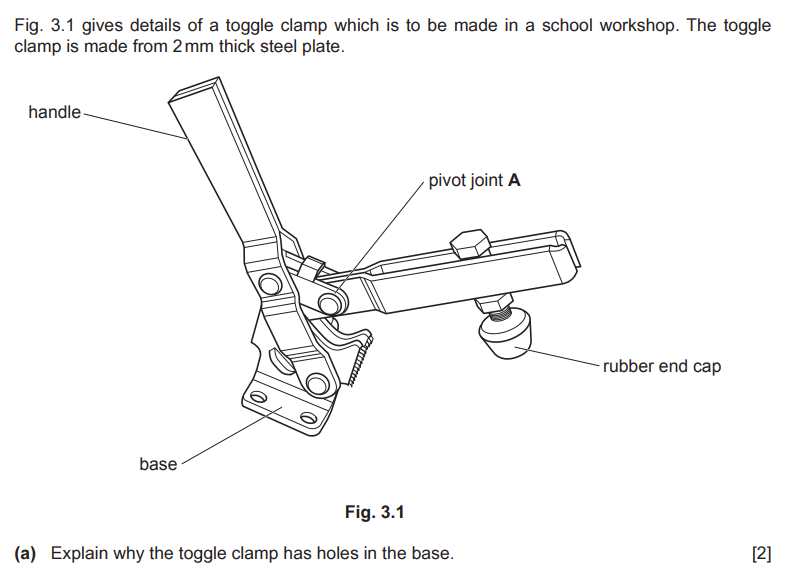

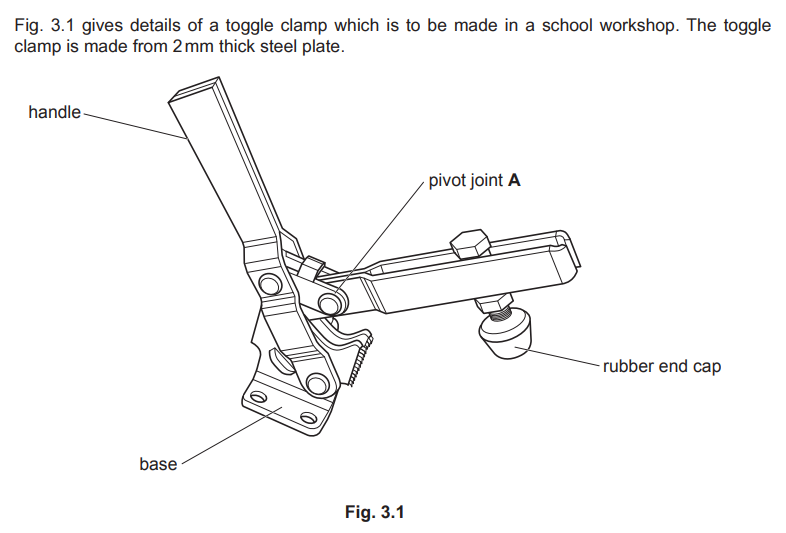

Sample examination questions (AS Design & Technology)

Examiner comment: Candidates gave a very wide range of different explanations of how to join part B to part C. However, there were some creative responses that included drilling holes in part C to allow part B to pass through and be fastened beneath.

Examiner comment: Most candidates could explain why the toggle clamp has holes in the base and often scored full marks.

Examiner comment: Candidates gave a very wide range of different explanations of a method to make joint A pivot and many found the question challenging.