It can be helpful for Design & Technology students to have an understanding of how to cut, drill, and shape metal. This article summarises basic metalworking methods and practical techniques.

Metal can be marked out with a scriber, which scratches the surface (shown left) and a steel ruler or try square. A center punch can be used to make hole locations. For curves, use calipers or carpenter dividers, and a center punch for creating marks for drilling.

Casting (Detailed information about casting needs to be studied by A2 students only)

- Metal is heated in a crucible (a heat-resistant container with a pouring lip used to hold molten metal – often made from materials such as graphite)

- Molten metal is poured into a mould (or injected in) and allowed to solidify into the desired shape. Examples:

- Sand casting (bit primitive, not high quality finish)

- Plaster of Paris casting (only works for non-ferrous metals)

- Die casting (a high-pressure manufacturing process that produces metal parts by injecting molten metal into a hardened steel mold, called a die – used for mass production of complex parts with high precision)

- Once cooled and solidified, the item is removed from the mould

Forging – Metal is heated and shaped through compressive forces using hammers or presses.

Rolling – Metal is passed through rollers to reduce thickness and create sheets, plates, or specific profiles.

Extrusion – Metal is pushed through a die opening to create continuous profiles with a fixed cross-section.

Drawing – Metal is pulled through a die to reduce its diameter and create wires or tubes.

Stamping/Pressing – Sheet metal is formed using dies and presses to create specific shapes through cutting, bending, or embossing.

Machining – Material is removed from a workpiece using cutting tools (turning, milling, drilling) to achieve precise dimensions.

Bending – Metal is clamped and bent manually, or heated for thicker parts and then bent, creating angles or curves.

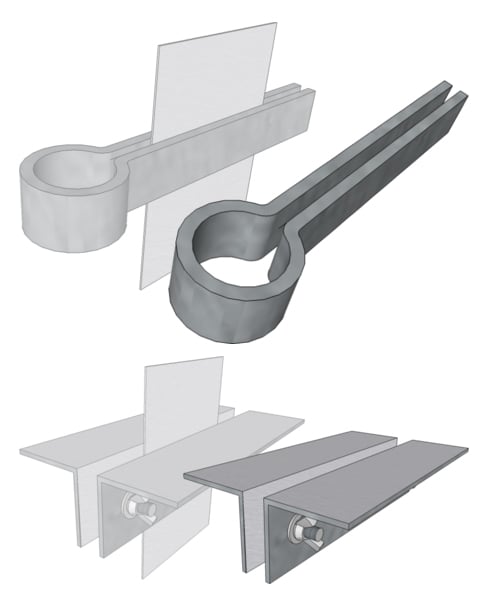

Folding bars can be used to hold and clamp metal to aid bending. (Image sourced from D&T Online).

Spinning – A flat metal disc is spun very fast and pressed against a shaped mold to make a round/circular part like a bowl or cylinder (can sometimes be heated slightly to bend more easily, but the shaping is applied by pressure, not with the metal in molten form).

Powder Metallurgy – fine metal powder is pressed into a mould under high pressure to form a shape, then heated (but not melted) so the powder particles bond together into a solid part.

Grinding – An abrasive wheel or belt removes small amounts of material to achieve precise dimensions, smooth surfaces, or sharp edges. It’s typically used as a finishing process after other forming operations, but a grinder can also be used to cut through metal.

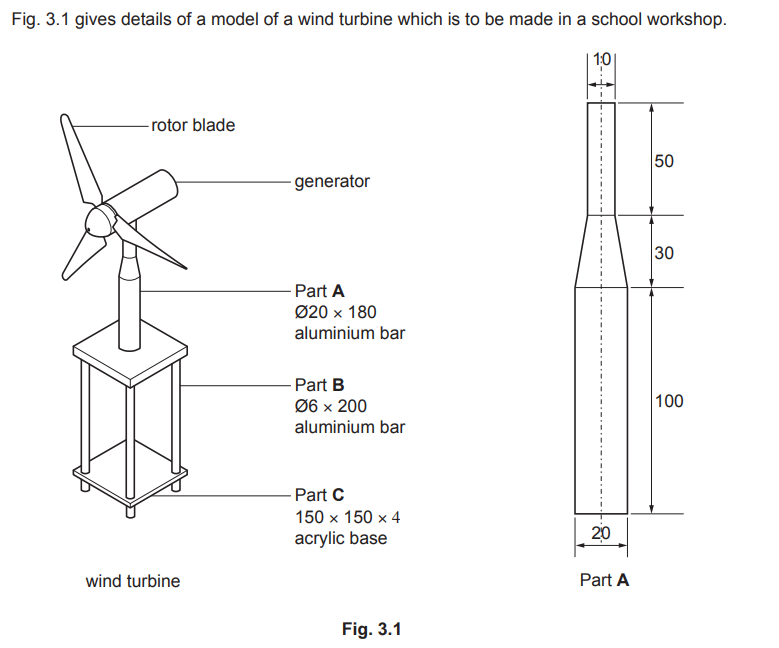

Centre lathe – as with using a wood lathe, metal can also be turned, making cylindrical or conical objects with parallel or tapered sides.

- Metal lathes are known as ‘centre lathes’ (heavier and more robust that wood lathes)

- Rather than being screwed to a face plate, the piece is held in a chuck (like how a drill bit is held by a drill) or between centres

- Metal turning tools (rather than chisels) are clamped to a tool post (not hand-held)

Manual cutting with hack saw

Normal saws cannot cut metal (the teeth on the blade break or get blunt) – instead a hacksaw is used.

Tin snips

Very thin sheets of metal can be cut with tin snips (basically extra tough / durable scissors for metal – normal scissors get blunt if you use them to cut metal)!

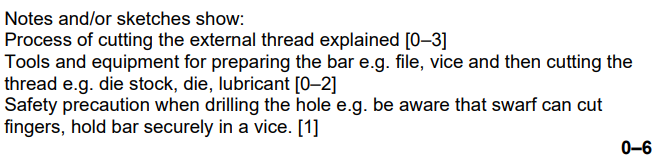

How to cut thread (enabling a metal part to screw in)

Cuts thread on rods / bars etc

- Secure bar in a vice ensuring it is clamped tightly

- Use a file to chamfer the end (remove the sharp corner/edges) to help the rod go through the threading die

- Select a threading die (a circular cutting tool with internal cutting teeth) of the right diameter i.e. M8

- Place the die in a die stock (a handle that holds the die)

- Apply lubricant (cutting oil) to reduce friction and heat

- Turn the die stock clockwise to cut the thread (reverse occasionally as needed)

- Continue until desired thread length is achieved

- Be careful of swarf (metal shavings) as they are sharp and can cut fingers / go into eyes

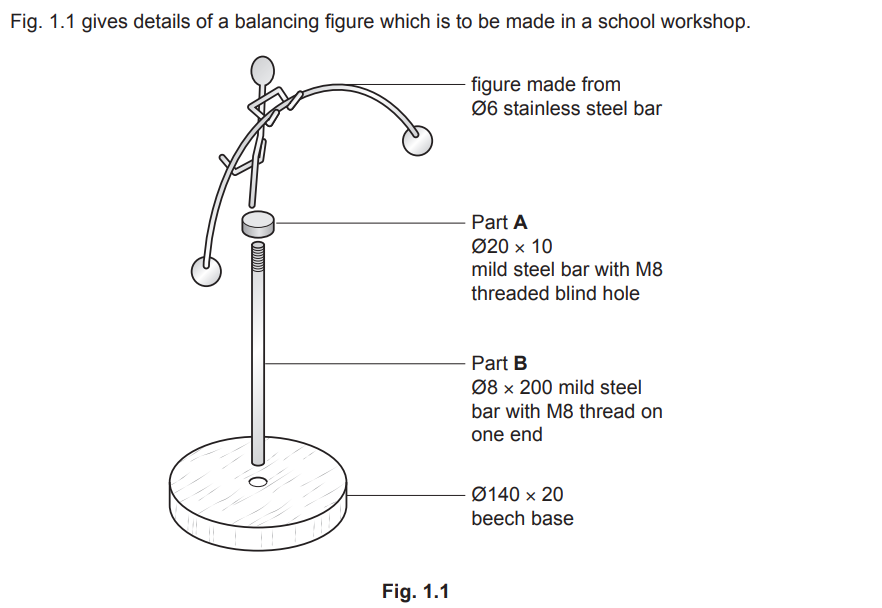

Cuts internal thread in holes

- Secure item in a vice ensuring it is clamped tightly

- Drill a pilot hole of the correct diameter for the tap size (e.g. for M8 thread, drill a 6.8mm hole)

- Use a countersink bit to chamfer the hole entrance to help guide the tap in

- Select a tap of the right size/thread pitch (e.g. M8) – a tap is made of hardened steel so it cuts into softer metals

- Insert the tap into a tap wrench (the handle that holds the tap)

- Apply lubricant (cutting oil) to reduce friction and heat

- Keep the tap perpendicular to the surface (this is critical to avoid breaking the tap)

- Turn the tap wrench clockwise to cut the thread, reversing occasionally to break the swarf/chips

- When done, remove the tap by turning it anticlockwise

- Be careful of swarf (metal shavings) as they are sharp and can cut fingers / go into eyes

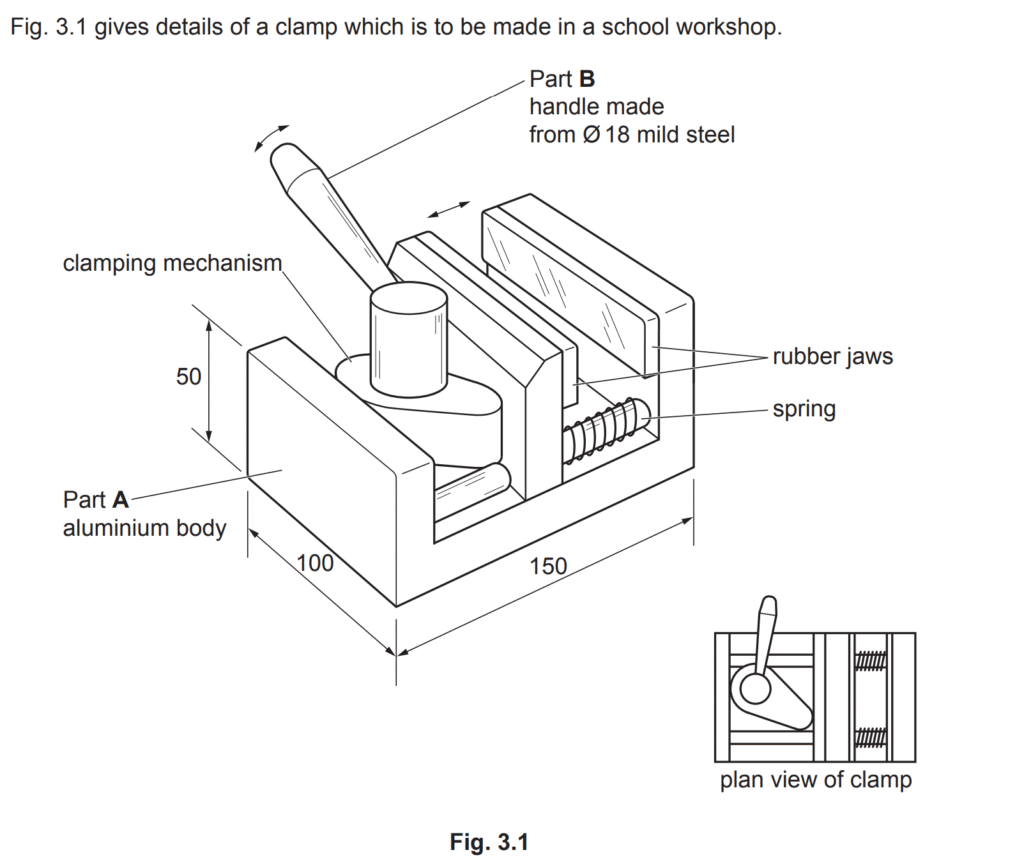

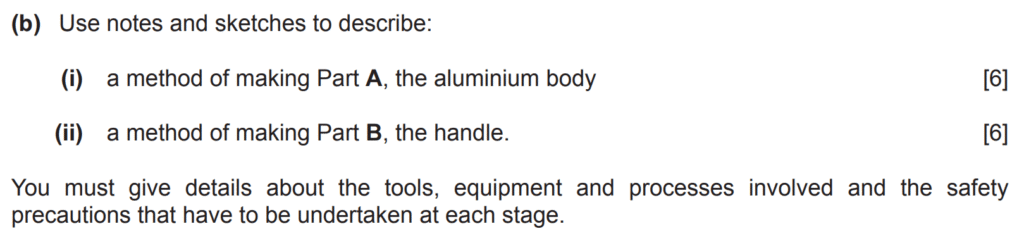

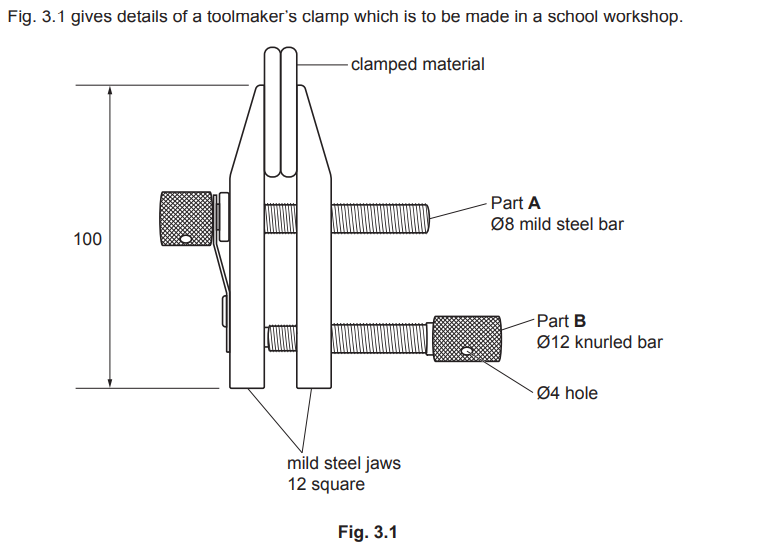

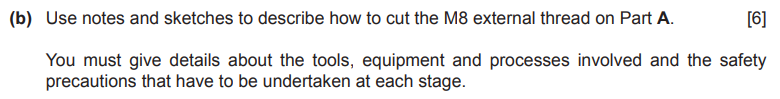

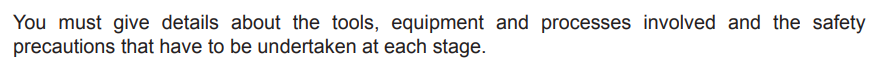

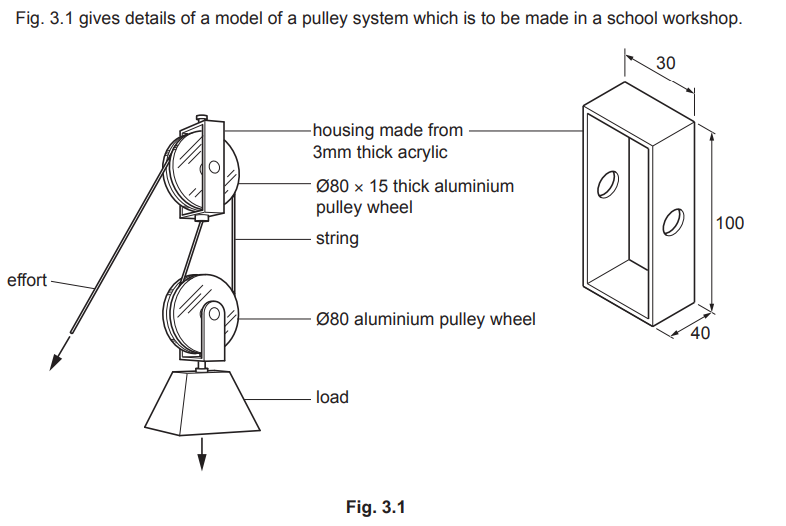

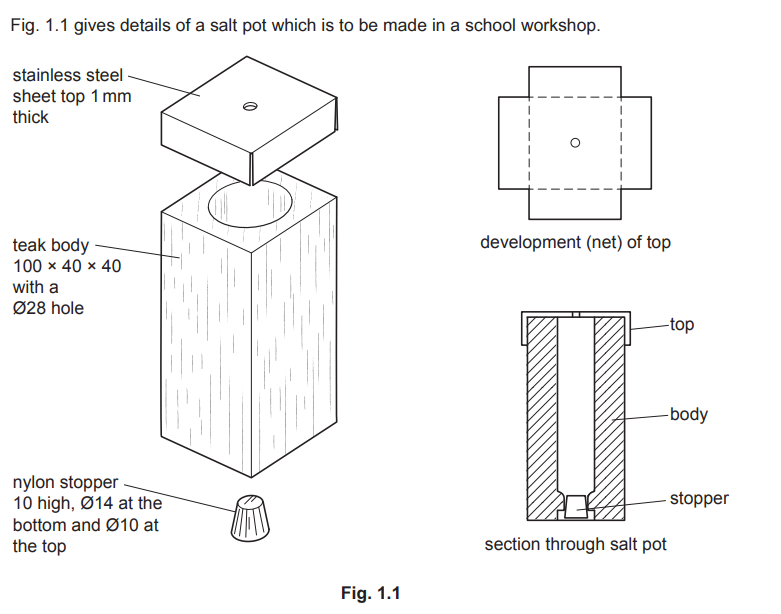

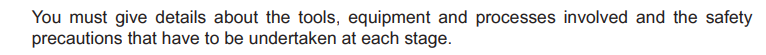

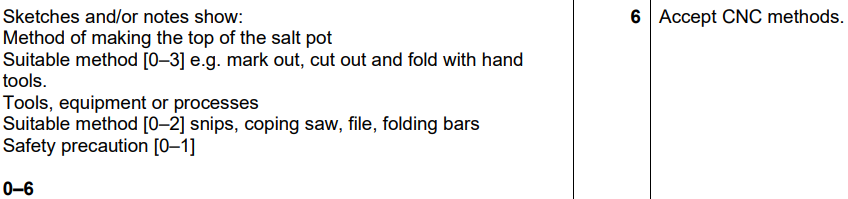

Sample examination questions (AS Design & Technology)

Examiner comment: Candidates were generally able to explain how to cut an M8 external thread on Part A with technical terms for tools and equipment accurately communicated.

Examiner comment: Stronger answers clearly described drilling the hole and tapping out with the use of lubricant. Many candidates used technical terms for the tools and equipment used. Safety precautions were not always included. Some candidates misunderstood the question and explained how to cut a thread

on part B with a die stock.

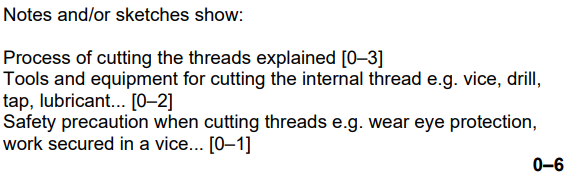

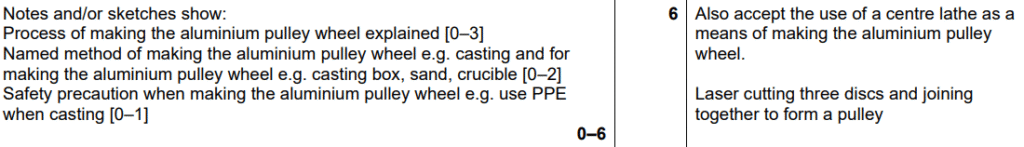

Examiner comment: Candidates gave a variety of different responses for making one aluminium pulley wheel. The most popular correct responses were sand casting or the use of a laser cutter to cut out three disks which were then connected together

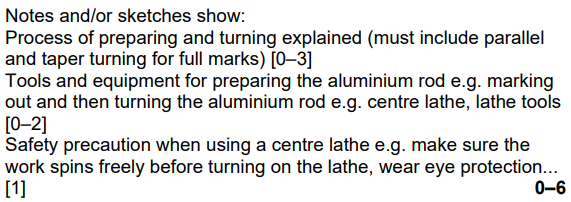

Examiner comment: Candidates found it challenging to explain how to make part A. Very few candidates were able to communicate in detail how the lathe, with both parallel and taper turning, could be used. Safety precautions were not always included or were generic.

Examiner comment: Stronger answers detailed marking out, cutting out and folding of the top. Most candidates used technical terms for the tools and equipment used. Safety precautions were not always included. However, some candidates gave die casting as a process, which was incorrect.