Many high school Design and Technology students complete practical projects in a school workshop. In this environment, students need to be aware of health and safety protocols and risk assessment procedures used within a school workshop. This includes understanding how to correctly use of hand and machine tools, identify hazards, and take relevant precautions as necessary. This article outlines some of these guidelines to ensure that students keep themselves and others safe when designing and making practical products.

Note: An understanding of health and safety practices should be clearly demonstrated in the realisation section of your coursework portfolio when constructing your final model or finished product.

Why is health and safety a crucial consideration within a school workshop?

- Safety of students and staff: The protection of students’ physical wellbeing is the primary responsibility of educators in workshop environments. This responsibility is paramount because young people may lack experience with tools and machinery and may not naturally recognize potential hazards. For example, in a graphic products workshop, students must be trained to use craft knives, steel safety rulers, and cutting mats and supervised to prevent accidents.

- Legal requirements: Formal risk assessments are legally required and provide a systematic approach to identifying and mitigating potential hazards in schools. Schools have strict health and safety policies which not only affect the wellbeing of students, but help to ensure schools meet safety regulations. When students are using equipment like laser cutters, risk assessments outline specific procedures such as proper ventilation requirements.

- Help students develop lifelong safe working habits: Students need to develop safe working habits and understand the consequences of unsafe behavior. These habits can then benefit students their whole lives – for example when doing DIY later in life. For example, when teaching students to use paper guillotines, clear demonstrations of safe finger positions and the importance of single-person operation must be emphasized.

- Reducing damage to machinery: Regular maintenance and inspection of tools and machinery is crucial for preventing accidents and ensuring reliable operation. This ongoing process helps identify potential hazards before they cause injuries. The regular checking of guard mechanisms on machines like laser cutters, and ensuring emergency stop buttons are functioning correctly, helps prevent serious accidents as well as helps ensure the machines are not damaged through incorrect usage.

- Understanding of emergency procedures: Clear emergency protocols and readily available first aid equipment are vital components of workshop safety. These procedures must be well-understood because quick response times can significantly impact the outcome of any incident. Having clearly marked fire exits, emergency stop buttons, and first aid stations, along with regular drills, helps ensure appropriate responses to emergencies. Undertaking regular risk assessments helps students and staff prepare for emergencies and know how to respond.

General safety practices for woodworking machinery or chemical processes

- Ensuring familiarity with operational instructions and receive training from a teacher before using a tool, machine, or new process involving corrosive or toxic materials;

- Always ask permission before using machinery and ensure a teacher is nearby to supervise or assist (always working under supervision);

- Never leave machines or hazardous chemical processes unattended;

- Wear appropriate personal protective equipment (PPE) for the relevant machine or process, such as goggles or visor to prevent from flying woodchips, face mask to protect from toxic fumes, gloves to protect hands from hazardous chemicals or excess heat, and an apron or lab coat to protect clothing and skin from chemical spills;

- Tie long hair back, roll up sleeves, and remove ties;

- Keep working areas clean to avoid tripping and slip hazards due to sawdust and off-cuts; to minimise fire risk; to ensure safe access and storage of tools; and to ensure safety exits are clear and unobstructed;

- Use correct tools for the job, following instruction manuals and directions of supervisors, using tools in appropriate ways with safety guards around blades and other hazardous components when required;

- Receive safety training before using corrosive or toxic materials (such as before mixing epoxy resin) and before using equipment or tools;

- Understand that electrical tools and chemical processes carry risk and be alert for potential hazards at all times – stopping immediately when needed.

WORKSHOP SAFETY PRECAUTIONS

Craft knife

Safety precautions

Laser cutter

Safety precautions

Vacuum forming

Safety precautions

Scroll saw / woodworking machines

Safety precautions

Welding

Safety precautions

Why manufacturers undertake risk assessments

- Better emergency response: Conducting risk assessments helps to facilitate appropriate response to hazards, encouraging staff to think through action plans in case something goes wrong. It can help ensure staff are well prepared and trained for various eventualities. A risk assessment can also help health and safety officers to target their efforts and produce training materials for workers.

- Safety of workers: Risk assessments are crucial for ensuring the safety of employees in manufacturing environments. By identifying potential hazards and implementing preventive measures, companies can significantly reduce workplace accidents and injuries. For example, a packaging manufacturer might conduct a risk assessment that reveals the need for improved ventilation systems to protect workers from paper dust and adhesive fumes when producing cardboard displays.

- Legal compliance: Undertaking risk assessments is often a legal requirement in many industries. Manufacturers must comply with health and safety regulations to avoid fines, legal action, and potential shutdowns. For example, in New Zealand, food production has stringent safety requirements, and any premises operating with unsanitary conditions has their business closed until the situation is remedied. Conducting risk assessments in advance helps to prevent this.

- Cost reduction: While conducting risk assessments requires an initial investment, they can lead to significant savings in the long run. By preventing accidents, equipment failures, and product defects, companies can avoid expensive downtime, repairs, and liability claims. A corrugated cardboard packaging supplier might use risk assessments to identify and mitigate potential die-cutting machine failures, thus avoiding costly production interruptions.

- Equipment protection: Regular risk assessments help prevent damage to expensive manufacturing equipment and minimize downtime. When using complex machinery like digital printing presses or automated folding equipment, understanding potential risks helps prevent catastrophic equipment failure and maintains production efficiency. This helps prevent expensive mistakes or production delays.

- Promotes a positive reputation: Risk assessments help protect brand reputation by preventing quality issues or safety concerns – developing a reputation for keeping workers safe and producing safe products. A well-managed manufacturing process with proper risk mitigation measures in place helps build trust with customers and the general public.

- Improvement in working conditions: Regular risk assessments can highlight areas for process improvement in existing systems. By evaluating manufacturing processes, companies can identify inefficiencies and opportunities for improved safety. A custom packaging company might use risk assessments to identify bottlenecks and challenges in their prototyping process, leading to the adoption of 3D printing technology for faster and safer sample production.

- Employee morale and productivity: When workers see that their employer is actively working to identify and mitigate risks, it can boost morale and productivity. Employees feel valued and protected, leading to increased job satisfaction and engagement.

- Helps provide data for staff training: Through risk assessment, manufacturers can identify where additional staff training is needed. This ensures operators are properly qualified to use equipment like digital cutting tables or automated assembly systems, reducing the risk of accidents or quality issues.

Students should also be able to recognise basic safety symbols used in the workshop, such as a skull and cross-bones to indicate that a chemical is hazardous.

Students should also understand actions to be taken when hazards are identified or when accidents occur in a school workshop or practical area, such as:

- Pulling the emergency stop cord to deactivate power if an accident with a machine occurs

- Notifying a teacher immediately

- Sending a student for the nurse

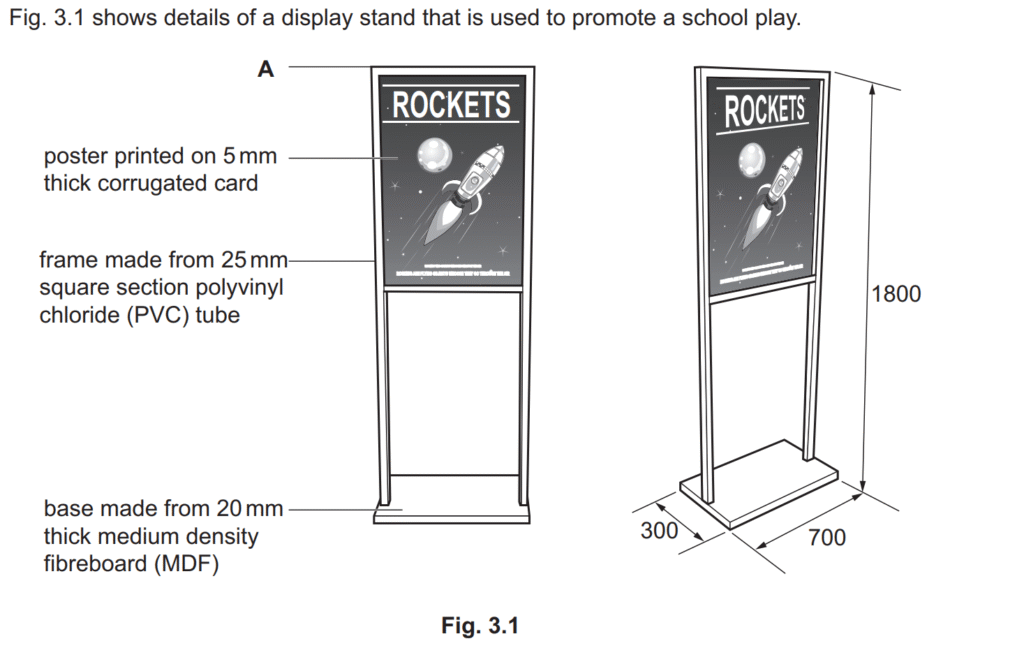

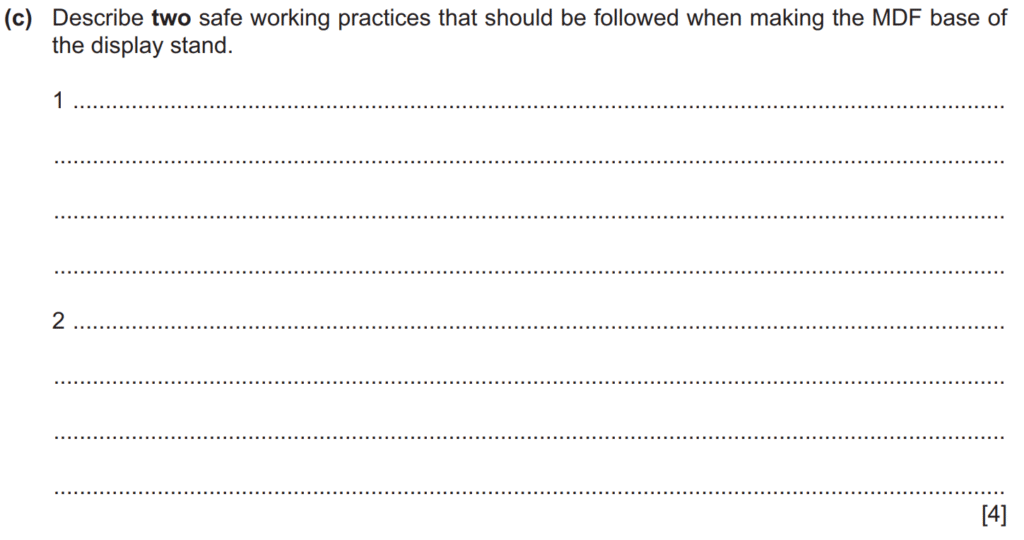

Sample examination questions (AS Design & Technology)

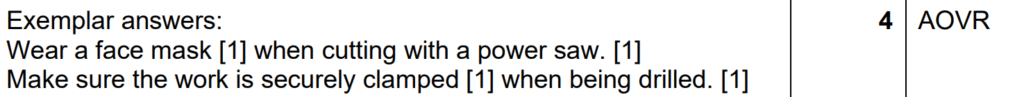

Examiner comment: Most candidates were able to describe two safe working practices that should be followed when making the MDF base of the display stand. Common answers included wearing a face mask when cutting the MDF with a power saw to avoid inhaling dust particles or making sure eye protection was worn and all guards were in place when drilling the MDF to prevent dust particles entering the eyes.

Some candidates only partly answered the question as they named Personal Protective Equipment (PPE), such as goggles, but it was unclear what manufacturing process was being undertaken or why the PPE was being worn. The use of gloves was often uggested, but it was not always appropriate to the task.