High school Design & Technology students often have to be familiar with a range of appropriate timber finishing techniques and surface treatments and understand how to choose between different wood finishing methods. This article summarises this topic and concludes with sample examination questions.

What is meant by timber finishing? (A definition)

Timber finishing refers to the various surface treatments and protective coatings that are applied to wood surfaces after construction or manufacturing, to improve performance or aesthetics.

What is the purpose of timber finishing?

- Protects timber – providing a barrier to moisture, UV rays, insect infestation, and so on, extending lifespan and preventing rot, warping, or cracking

- Improves functionality – such as creating a smooth surface that is easily wiped clean

- Improves durability – makes surface more resilient, protecting against wear

- Aesthetic enhancement – highlighting natural grain and colour of wood or changing natural appearance of the timber with stains, paints, or laminated coatings

What influences the choice of timber finishing solution?

- Type of timber or manufactured board – some timbers accept stain, varnish, and paint better than others (for example, teak contains natural oils that prevents finishes from properly penetrating and adhering to the wood surface)

- Intended use

- Indoor / outdoor – i.e. exterior paint must have UV protection, moisture resistance, and flexibility to handle temperature swings and exposure to weather conditions

- Contact with food – i.e. cutting boards and countertops require food-safe finishes like beeswax or polyurethane, and wooden floors need very thick, resilient, and durable finishes that can be easily mopped clean like polyurethane

- Moisture exposure – kitchen benchtops or bathroom floors must be much more water resistant than a wooden wardrobe for example

- Desired appearance – for example, a melamine laminated layer (pronounced “meh-luh-meen”) can make a material look like something totally different

- Maintenance requirements – some finishes are harder to upkeep than others (i.e. another layer of linseed oil can just be brushed over the top after wiping the product clean, whereas re-varnishing requires sanding all the old varnish off – although oils must be reapplied more frequently)

- Cost – including initial and maintenance costs

- Difficulty of application – i.e. linseed oil can just be brushed on, with excess oil wiped away, whereas varnish often requires multiple thin coats with careful sanding in between, avoiding getting dust in the layers

- Drying/curing time – some have multiple coats with long drying times, whereas laminated melamine MDF or particleboard panels can be purchased premade

How to prepare timber for finishing

This depends upon the method of finishing, but the approximate process is as follows:

- Ensure timber is dry (ensures proper adhesion of coatings)

- Fill any holes or imperfections with an appropriate wood filler that matches the timber colour (optional)

- Sand the wood surface thoroughly, sanding in direction of grain, moving from rough grit to fine grit sandpaper

- Wipe off all dust completely with a microfibre cloth

- Apply a primer or sealer (undercoat layer) if required, helping prevent natural chemicals in the wood bleeding through the top coat (especially from knots) – this helps the top layers bond well to the surface, fills any minor imperfections (making the top coat smoother), and helps prevent the wood absorbing too much of the top coat, making a shinier finish

- Apply coating (multiple layers as required, ensuring completely dry in between, and sometimes requiring sanding between layers)

Types of wood finishes

SURFACE FINISHES & TREATMENTS FOR TIMBER

Varnish or polyurethane

Properties

Some oil-based polyurethanes have better heat resistance and can be useful for tables that must support hot coffee mugs etc.

UV lacquer

Properties

Linseed oil

Properties

Paint

Properties

Paints and other coatings are typically available in a range of surface qualities: gloss = shiny, matte = not shiny, satin = halfway in between

Wood stains

Properties

Melamine coatings

Properties

Uses

Paint thinners are solvents that can be used to dilute paint, or to clean brushes, or to strip old paint from surfaces.

Note: In manufacturing and design contexts, lamination and veneers are often grouped with other finishing techniques because they serve the same end goals – improving the final surface properties and appearance of a product. These are thin layers of other materials that are glued or bonded to another material.

Some modern flatbed printers can print directly onto wooden surfaces, adding graphics and text to sheets of plywood and other wooden items – useful for signage.

Note: Some timbers are self-finishing and do not require treatment.

Wood cannot be made truly heat resistant, however fire-retardant coatings can be added to provide fire protection to structural elements. High temperature paints and lacquers can also be used.

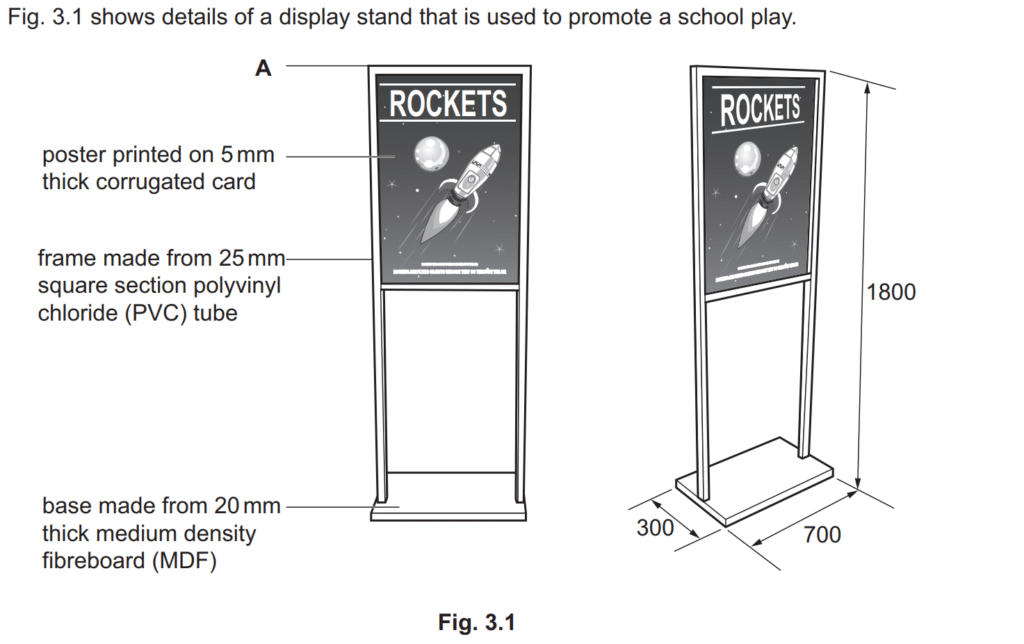

Sample examination questions (AS Design & Technology)

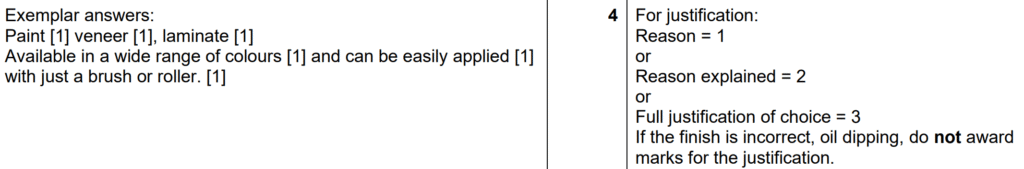

Examiner comment: Many excellent responses were seen to this question. Most candidates were able to identify a suitable finish for the MDF and gave some reasons for their choice. The justifications were usually well reasoned and based upon accurate knowledge of the material and the proposed finish. The most frequently seen finish was paint, with the justification focusing on its availability in a wide range of colours, being relatively cheap to purchase, easily applied with a brush or roller and able to give an attractive finish that is durable and long lasting. Other finishes that were proposed

included varnish and a melamine-faced laminate.