This revision guide helps you prepare for the Cambridge AS Level Design & Technology exam (9705/01 Written Paper 1). This material covers the new Cambridge syllabus, examined for the first time in 2025 and acts as a digital textbook. It links to detailed explanations and sample questions to help you learn this material.

Examination Format

The AS Level Written Paper is 2 hours 15 minutes long.

There are 100 marks available and you must answer all questions.

Based on the sample exam paper provided, it is organised into approximately the following sections:

| Description | Marks | |

| 1 | Materials & Components | 8 |

| 2 | Communication / Drawing methods / CAD | 8 |

| 3 | Graphic products | 20 |

| 4 | Hard materials | 20 |

| 5 | Electronics / energy / emerging technology | 20 |

| 6 | Inclusivity / accessibility (design modification question) | 12 |

| 7 | Cultural, economic, environmental, social factors, design movements, fashions/trends (extended response question) | 12 |

| TOTAL | 100 |

The examination is worth 50% of your final AS Design & Technology grade.

Bring to the exam

- Black or dark blue pen (for written answers)

- HB pencil (plus a backup pencil)

- Pencil sharpener

- Eraser

- Standard drawing equipment: ruler and protractor

- Colouring pencils

- Calculator

Answer format – general tips

Exam questions are typically formatted using a few key phrases. These indicate the type of answer that is required. Cambridge examiners have provided sample answers to help you familiarise yourselves with the layout of the new paper.

“Name…” questions

IMPORTANT TIPS

- These are short answer questions

- No further details are necessary (check to see if this the question is worth 1 mark to confirm)

- Precise names must be given (i.e. acetate sheet ✓ rather than plastic X)

- Acronyms are accepted (i.e. MDF ✓, although examiners prefer the full name such as medium density fibreboard ✓)

“Explain…” questions

IMPORTANT TIPS

- Justify comments, providing reasons and further explanations. In other words, don’t just state facts, but provide the evidence or justifications for this. For example, “Two point perspective drawings are very realistic” [stating fact] “as objects that are further away appear smaller” [further explanation providing evidence/justification]

- In the health and safety question, a health and safety procedure is identified [1 mark] with explanation of how this applies to the manufacture of the child’s trolley [1 mark]. In other words, the point is stated, followed by more evidence / explanation.

- If you have a choice of possible areas to discuss, choose methods that you are most familiar with (for example, if you have used an orbital sander, but not using the drill press, focus on examples like that).

- Check number of marks available – often one reason is asked for, but two marks are available. This is because you must demonstrate knowledge/understanding [1 mark] and then explain why [1 mark]

- In questions where you are asked to name and then explain something, even if the name is incorrect, you can be awarded marks for the explanation, if that part is correct, so make sure you answer the whole question

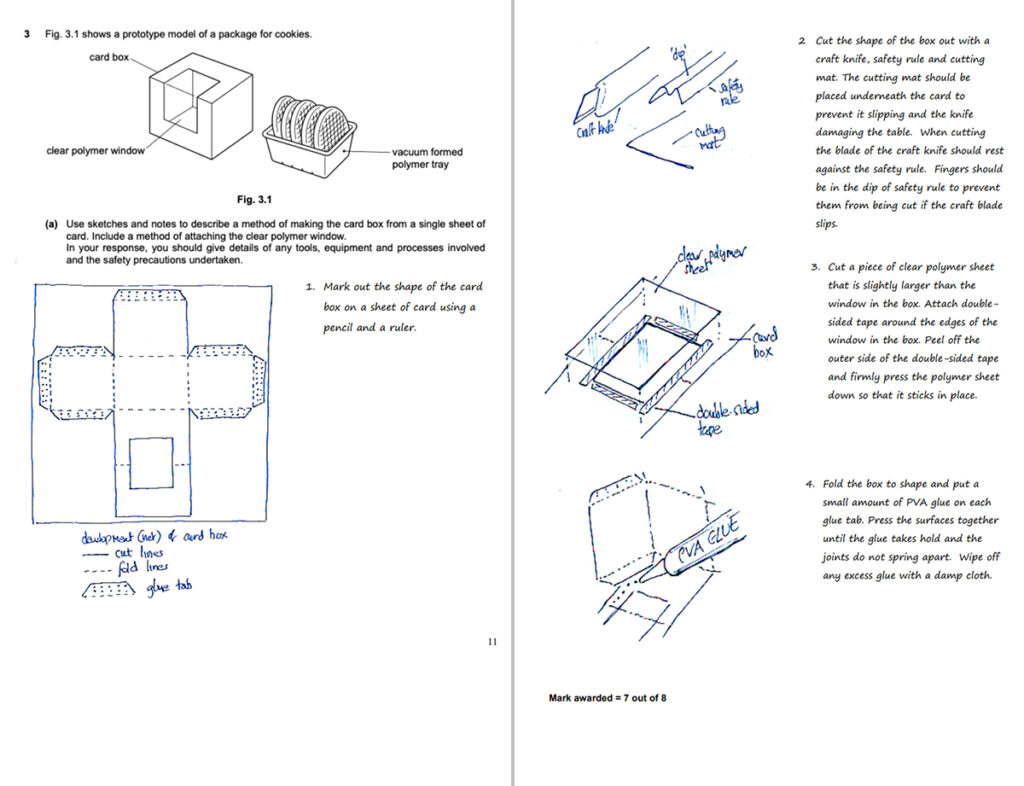

“Use sketches and notes to describe…”

IMPORTANT TIPS

- Organise the answer in a clear step-by-step format

- Ensure the sequence is spaced nicely across the page, rather than crammed up (make it easy for the examiner to follow)

- If some time of net is involved, sketch nets accurately with glue tabs and fold lines (long dash, two short-dashes)

- Ensure accurate names of tools are used and accurate material / component names

- Ensure methods of cutting, joining, fixing, and finishing are clear (if required)

- Ensure steps are in a logical sequence

- If a net – don’t forget scoring lines and folding up the box (commonly forgotten step – and is missing from the example above, hence why it was awarded only 7/8 marks)

- Choose a process you are familiar with (common, simple processes explained well are better than complicated processes explained poorly)

- Hand methods or CAD methods are usually acceptable, but check whether the question specifies a one-off / batch / or mass produced item

- Include safety precautions – make sure these are specific and appropriate

- Important notes: If sketches and notes are required, you should produce sketches and then add a few notes, rather than write lots of notes and add a few sketches (in other words, it should be a good balance of sketches and notes)

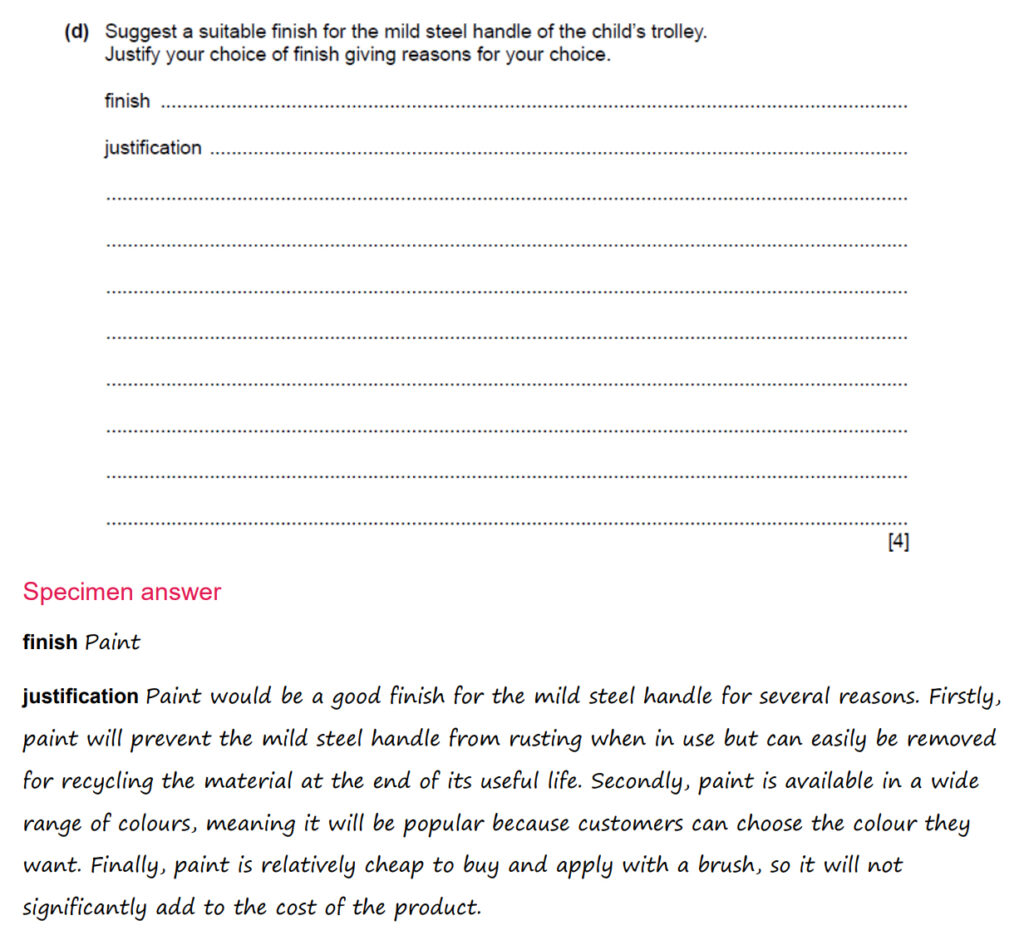

“Justify…” questions

IMPORTANT TIPS

- Choose processes you are most familiar with (as long as these are appropriate)

- Check how many marks are awarded (note in this example, three marks are given for the justification, hence three separate points are needed)

- CRITICAL POINT: The examiners note that the response has “justified why paint is a good finish for the mild steel handle by incorporating into their answer the wider issues in design and technology. For example, an environmental factor (ease of recycling), a social factor (giving customers a colour choice to make the product more popular) and an economic factor (cost of the paint).” “Candidates must incorporate cultural, economic, environmental and social factors into their justification, if they are to be awarded the higher marks” ***Note that they did not mention wider issues in this question, yet still expect it in the answer.***

- Each point should include the statement of fact, followed by further evidence / explanation / justification. To receive full marks for this type of question you need a fully developed response with at least two reasons fully justified.

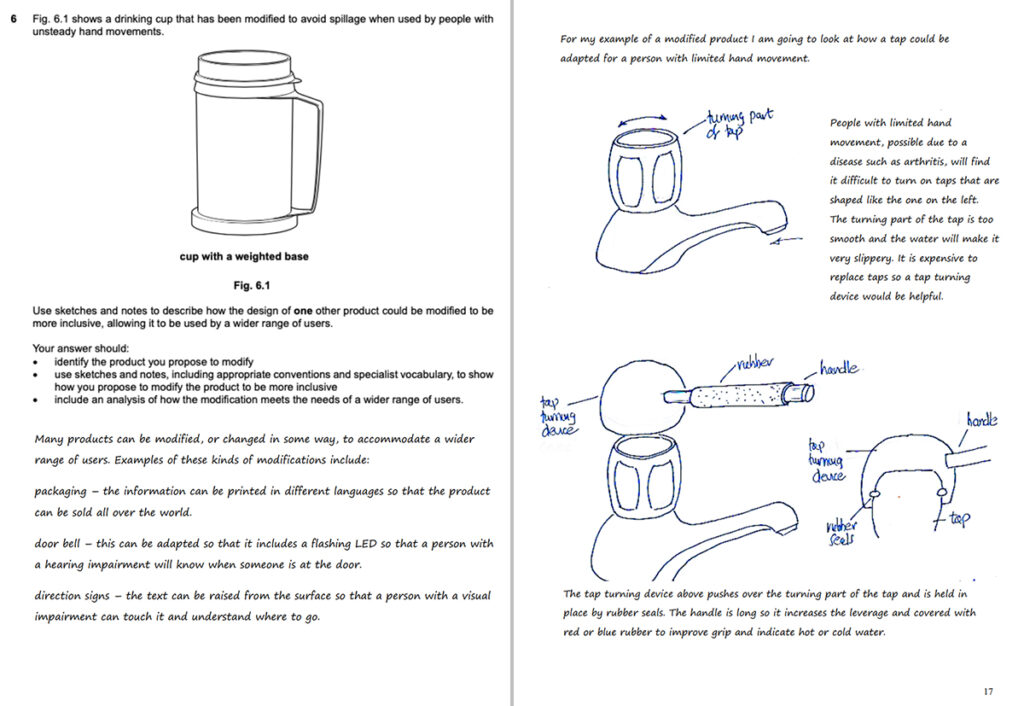

Design modification question

IMPORTANT TIPS

- Clearly name the chosen product

- Analyse the existing product, identifying the problems with the design in terms of the specified user group, discussing how it could be modified, comparing it to other products

- This question should have at least two main drawings (the original product, plus the modified / improved product) plus additional enlarged details, other small drawings using a range of graphical techniques (i.e. exploded drawings, sectional drawings), as necessary to communicate the new design

- Add annotations around drawings, noting technical details (including specific material names), with brief notes justifying and explaining choices

- Analyse the new improved design, discussing whether it would function as intended and be more accessible to the target users. (Also consider how this might affect affordability and usability by other users etc – for example, by making it more accessible to one group, are you making it less accessible to another?)

- Link comments to wider issues (sustainability, cost, social issues etc) i.e. “modifying an existing tap would be less expensive than fitting a new tap that is designed for a person with limited hand movement” or “replacing the taps would not be environmentally friendly unless the old taps were recycled” or “producing a product, such as a device to help people with limited hand movement to use a tap, would be expensive as the volume of sales is likely to be low” or “one social impact of producing a device to help people with limited hand movement to use a tap would be that they may become more independent.”

- To prepare for this question, you should practise modifying a suitable product to suit a specific context or group of users, i.e.: those with limited mobility, hearing impaired users, vision impaired users, neurodiverse users, users with language needs, children and young families, elderly users, users of a specific culture or a diverse multicultural community, or so that a product is more sustainable / easily repaired / energy efficient.

- You can choose the product you wish to modify. The chosen product might also relate to your own coursework product improvement project (this would mean you are extra familiar with it).

- Note that this question begins: “Use sketches and notes to describe…” so it should be a balance of sketches and notes, not mainly writing.

…the design modification proposals were often very impressive, but the analysis of how the modification would meet the needs of people with a visual impairment was sometimes rather superficial.

– Examiner Report, June 2025

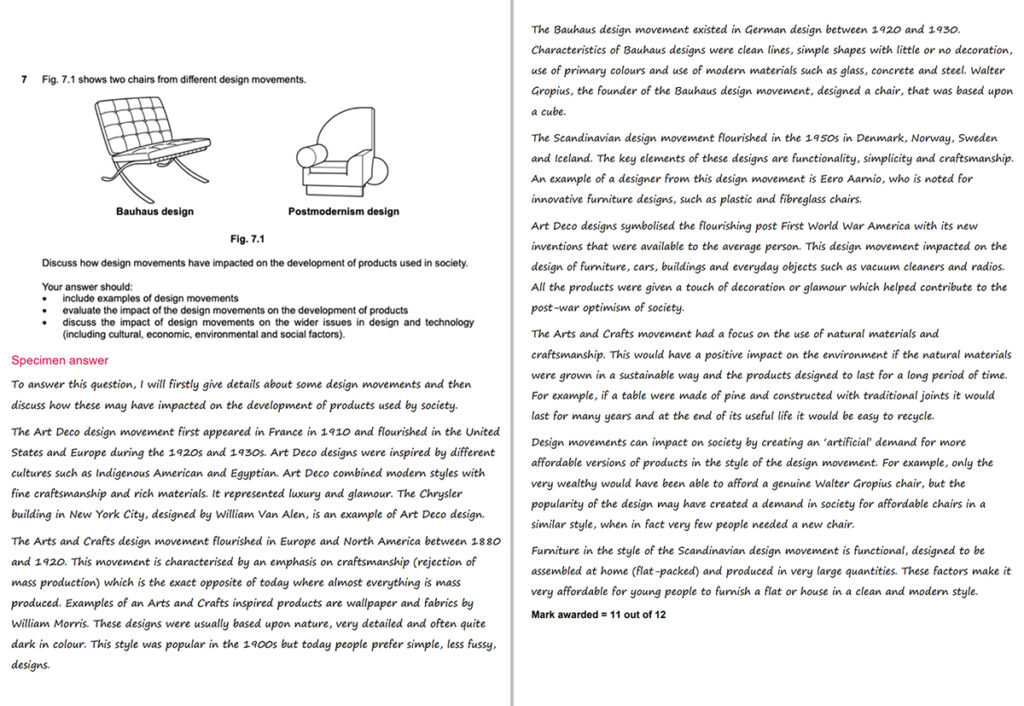

Extended response question

IMPORTANT TIPS

- Write in full sentences, with paragraphs, thoroughly analysing the situation

- Ensure you include appropriate examples (these might be of specific products, designers, design movements etc) to use as detailed supporting evidence for your arguments

- Ensure you link your discussion to wider issues in design & technology (including cultural, economic, environmental, and social factors). This means you should consider the impact of [the topic] on wider society. Examples from the sample answer above, as noted by the examiners:

- The use of natural materials, such as pine, would be good for the environment as they could easily be recycled (one wider issue)

- Design movements can create an increased demand within society for a new style of products (second wider issue)

- Mass-produced flat-packed products are very affordable (third wider issue)

- Three or more comments linking to wider issues must be included to gain high marks

View sample essay topics here.

Topics to Revise for AS Design & Technology (9705)

To prepare for this exam, revise the 12 separate topics listed below, working through each link on this page.

1. The design process

- How key stages in design thinking lead to the design process.

- The iterative design process, and why this is beneficial.

- The meaning of intuitive design and why we should aim to achieve this.

- Why specifications are written and how these help.

- The definition of primary and secondary research and how to use different market research tools (observations, interviews, questionnaires).

- The importance of modelling including what a prototype is used for.

- The difference between destructive and non-destructive testing and why it is important to test a product at different stages.

- How to evaluate a product (discussing pros and cons, linking to the user needs and the specification) in terms of function, aesthetics, ergonomics, materials, production processes, target market, cost, health & safety, quality control, societal impact, environmental impact / sustainability.

2. Design principles

- What is meant by Dieter Ram’s concept of “Good Design“.

- Key features of common design movements (Art Deco, Arts & Crafts, Bauhaus, Scandinavian, Minimalism, Modernism, and Postmodernism) and how these influence the design of products.

- The difference between a fashion and trend, and how these impact product design.

- Different scales of production (individual/one-off, batch, mass production), when these are suitable, and why they are chosen.

- How different economic factors influence material and production costs, including the availability of materials and the impact of new manufacturing technologies.

- How changing customer requirements, cultural changes, and other social factors influence design (including ways that design can have a positive impact on society).

3. Communication

- Common drawing methods, including exploded drawings, sectional views, isometric (including the construction of arcs and circles), orthographic projection / working drawings (including first angle and third angle and their symbols), one- and two-point perspective, assembly drawings, and planometric (45/45), and understand when these drawings may or may not be appropriate.

- Rendering to enhance drawings to represents, materials, surface, colour, and tone (light and shadow) – particularly rapid rendering methods suitable for an exam.

- Be able to draw nets, including fold lines (long dash, two short dashes), glue tabs and mechanical joining methods required to form prisms, cones, cylinders, and pyramids.

- Appropriate symbols and conventions including dimensioning and use of scales.

- Common planning drawings including Gantt charts, flow charts, and cutting lists.

- The impact of digital technology used to communicate including CAD software packages such as Microsoft Word, Microsoft Excel, Microsoft PowerPoint, Adobe Photoshop, Microsoft Teams and Mirovideo conferencing.

4. Design and technology in society

- The impact of design & technology on society and vice versa, including whether products are inclusive or exclusive for certain individuals (such as children, elderly, or those with particular needs such as visual impairment, hearing impairment, neurodiverse requirements, mobility or physical support needs) or different groups (different locations, religions, ethnicities and cultures).

5. Sustainable design

- Why designers and manufacturers have a responsibility to ensure products are sustainable, including legal requirements.

- Factors that impact sustainability, including type of materials (locally sourced, recycled, biodegradable materials), amount of materials, reduction of waste (offcuts, packaging), method of processing raw materials, energy consumption across the lifecycle (included during manufacturing processes, maintenance, and reducing transport costs, such as by flat-packing), ease of repair, ease of replacing parts through use of standardised components, and ease of disassembly and disposal).

- Labelling materials to aid separation for recycling (with the use of recycling symbols).

6. Health and safety

- Common health and safety procedures in a school workshop, including wearing appropriate PPE (goggles / welding goggles, visor, face mask, gauntlet, spats, gloves, apron or lab coat), tying up hair, rolling up sleeves and removing loose clothing. keeping workspaces tidy, using the correct tool for the job and using tools safely (safety guards, training before use, working under supervision.

- Standard risk assessment processes in design and manufacture, including identifying hazards and making risk assessments and understanding what to do if an accident occurs.

7. Aesthetics and ergonomics

- The importance of aesthetics (line, colour, shape, light, shade, surface finishes, proportion and form) and how these affect visual and tactile senses.

- The balance of form and function (these ideas are discussed in the design movements article, as well as when learning about aesthetics)

- The importance of ergonomics – designing environments, products and systems to fit the people who use them – including an understanding of common anthropometric measurements, including weight, height, knee height, sitting height, body mass index (BMI), body circumference (arm, waist, hip and calf) and waist-to-hip ratio (WHR) and how this can be interpreted.

8. Materials and components

- The meaning of material properties (hardness, ductility, toughness, brittleness, elasticity, malleability, dimensional stability, electrical conductivity, thermal conductivity, corrosion resistance).

- The working properties, stock forms and sizes, common uses and environmental impact of:

- Paper, cardboard, and other lightweight materials (copier paper, card, corrugated card, bleached card, mount board, duplex card, moulded paper pulp, foamboard, foil-backed and laminated card e.g. Tetra Pak®).

- Modelling materials (extruded polystyrene foam, e.g. Styrofoam™, balsa wood, polymorph, plaster of Paris).

- Wood and manufactured boards (softwoods, hardwoods, manufactured boards).

- Metals (ferrous metals and their alloys).

- Polymers / plastics (thermoplastics: acrylic (PMMA), nylon, polyvinyl chloride (PVC), polystyrene (PS), polypropylene (PP), high and low density polyethylene (HDPE) (LDPE), high impact polystyrene (HIPS), polycarbonate (PC), acrylonitrile butadiene styrene (ABS), polyethylene terephthalate (PET); thermosetting plastics: polyester resin, melamine formaldehyde (MF), urea formaldehyde (UF), epoxy resin; and elastomers: neoprene, silicone, thermoplastic elastomer (TPE); fibre reinforced materials: glass fibre reinforced plastic (GRP), carbon fibre reinforced plastic (CFRP); bioplastics: starch-based, sugar-based, cellulose-based).

- Examples of composite materials and why these are made.

- Examples of ‘smart’ materials (including polymorph; pigments: phosphorescent, photochromic, thermochromic; shape memory alloys (SMA): nickel, titanium; hydrogels; shape memory polymers).

- Examples of ‘modern’ materials.

- Examples of biodegradable materials (the working properties, common uses and environmental impact of polylactide (PLA), polyhydroxybutyrate (PHB) e.g. BIOPOL®, plastic made from corn/potato starch).

- Recognise and identify electronic components and symbols.

9. Stages in materials processing

- Common production stages (marking out from working drawings; cutting, shaping and forming of materials using appropriate tools and methods; joining and assembling; selecting and applying a finish which is appropriate for the material used and the product design), including representing these production processes in sequence drawings

- Common adhesives and suitable uses.

- Temporary and permanent joining methods for paper and card (tab and slot etc)

- Temporary and permanent joining methods for wood (including ways to strengthen structures, such as brackets, flanges, ribs, and bracing).

- Temporary and permanent joining methods for metal.

- Hand and machine cutting, shaping, and drilling methods: wastage cutting with hand and machine tools including laser cutter, vinyl cutter, drilling (hand drill, powered and press drills), turning (wood lathe and centre lathe), milling and routing, abrasives:

- Cutting/shaping paper, card and other lightweight materials

- Cutting/shaping wood

- Cutting/shaping metal

- Plastic forming methods including vacuum forming (including the design and construction of formers) and line bending.

- Approaches to fabrication (addition of parts and components), including adjustable designs and flat-pack.

- Printing methods (digital printing and screen printing)

- Finishing methods (paints, polymer coatings, varnishes, including UV and spot varnishing):

10. Energy and control systems

- Energy use in product design, including:

- The main sources of energy and why and how they are used in manufacturing products : fossil fuels such as oil, natural gas and coal (finite); water, wind and solar (renewable).

- Different forms of energy: kinetic, potential, thermal, electrical, chemical.

- Practical methods of energy conversion from one to another through simple mechanisms, machines, engines, turbines and electric motors.

- Basic principles of manual, semi-automatic and automatic control using input, output, feedback and amplification.

11. Technology

- The benefits of CAD (Computer Aided Design) for storing data and manipulating images.

- Common features of CAM (computer-aided manufacture), particularly in the control/operation of machines.

- How emerging technologies impact on designing and manufacturing products (understand the terms invention, innovation, and evolution), including 3D printing, rapid manufacture, robotics, artificial intelligence (AI), and virtual reality (VR).