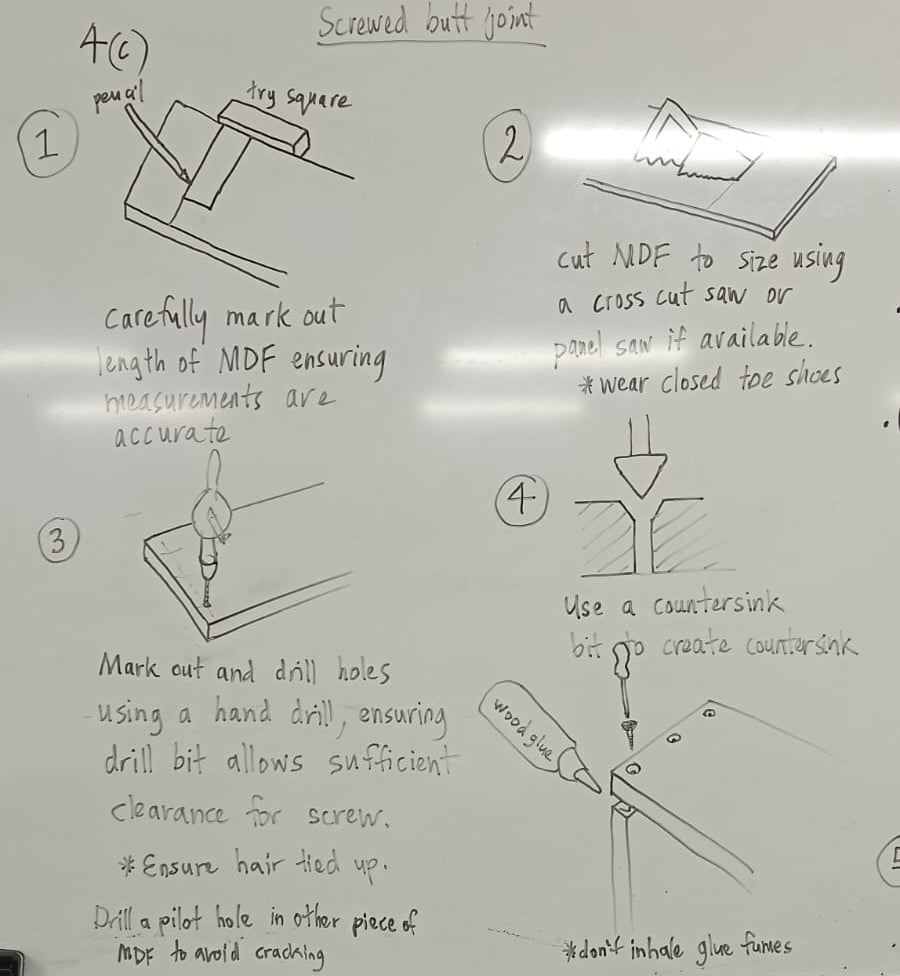

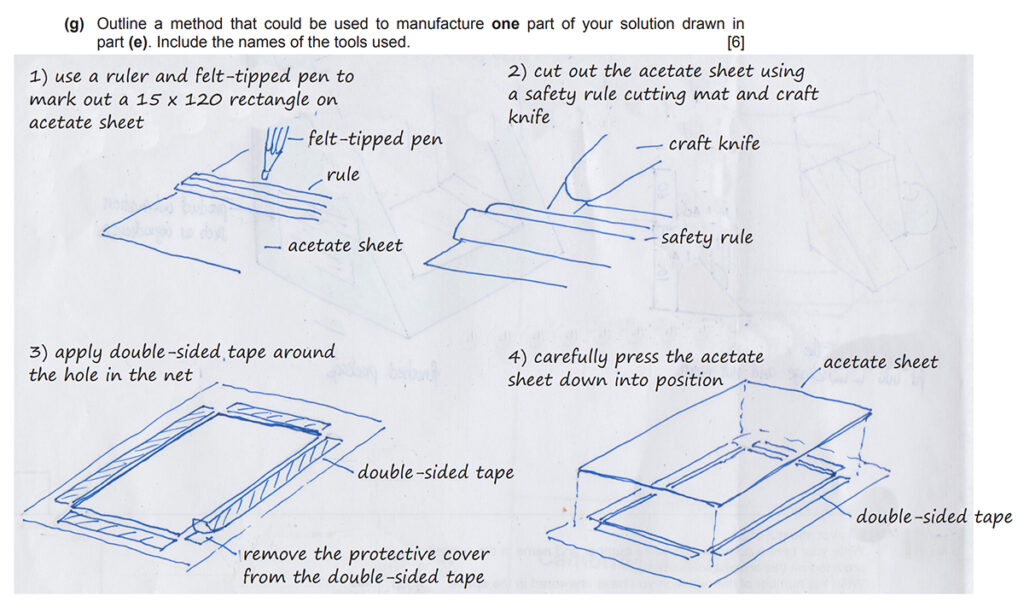

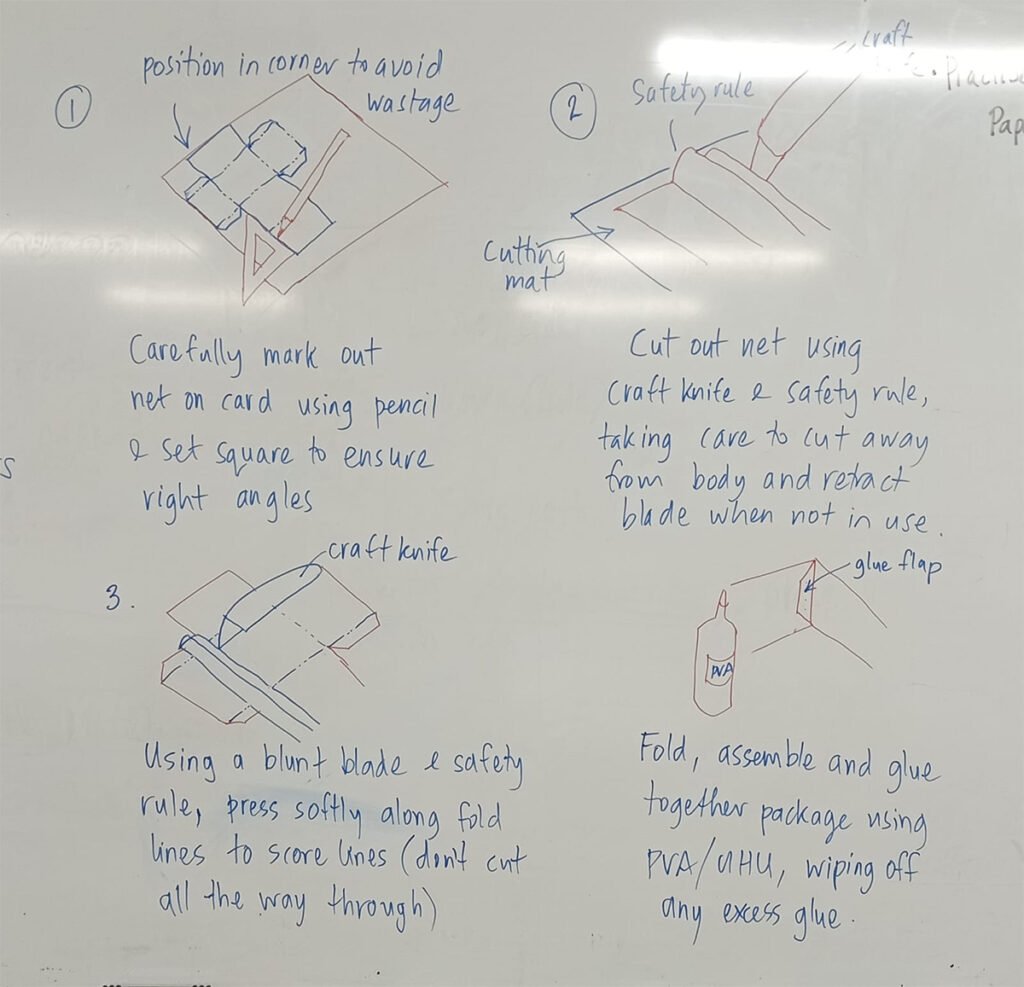

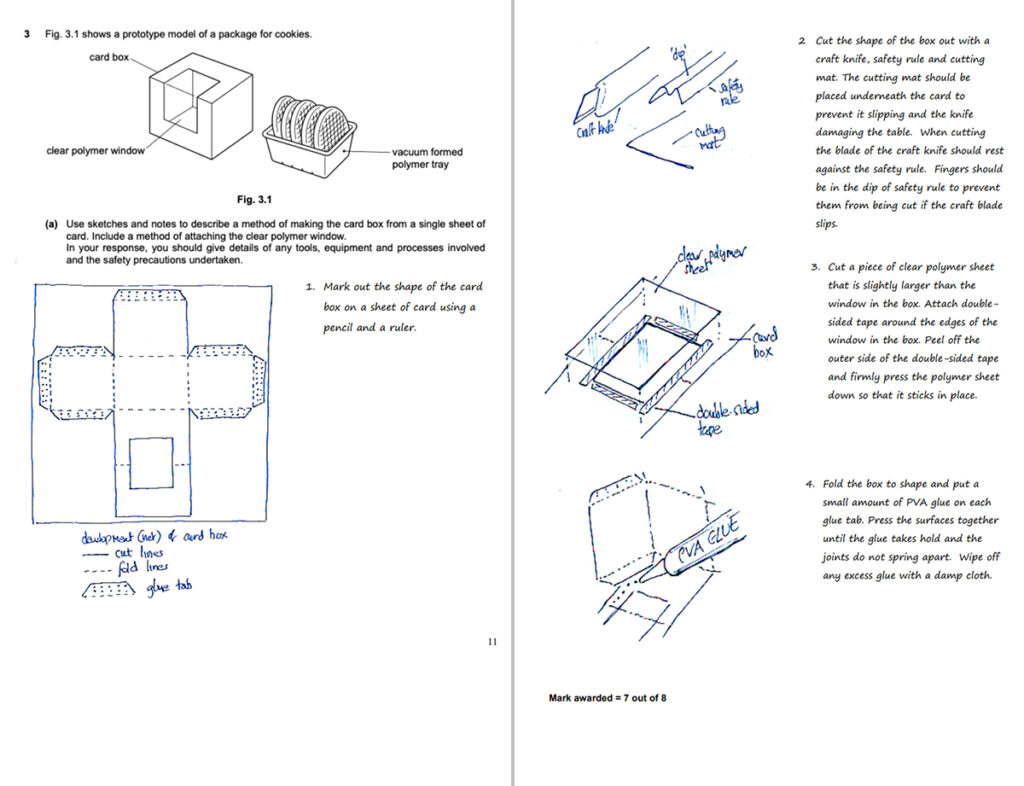

Cambridge Design & Technology students often have to produce diagrams illustrating a particular production process. This typically involves sketches and diagrams organised in sequence, showing step involved: gathering materials, marking out, cutting, shaping/forming, joining, fitting, assembling and finishing. Here we offer key guidelines for answering these questions and provide several examples, illustrating possible ways of formatting answers.

Production processes used in lightweight graphic products

Don’t forget to include the process of scoring lines

- Scoring means to make an indentation in the surface of a material that acts as a fold line

- Helps make clean, straight, precise fold lines

- Prevents cracking or tearing of the material when folded

- Made using a scoring tool (often a dull scalpel blade, back of a knife, or wheel) is pressed into the material.

- This creates a shallow depression without cutting through the material

- The depth and width of the score line can be adjusted based on the material thickness and desired fold

- Can be manual or by machine for large-scale production of packaging etc

Other production processes (AS/A2 students only)