This article summarises different ways to join card and other lightweight materials in graphic products, including temporary joints, permanent joints, pop-up features, and rotating mechanisms. It concludes with examination questions to help you revise this material.

Permanent joints cannot be undone without damaging the material (these joining methods are not intended be taken apart afterwards).

PERMANENT LIGHTWEIGHT JOINTS

Glue tabs

Properties

Uses

You must mention an appropriate glue for the material. See different adhesives here.

Double-sided tape

Properties

Uses

Staples

Properties

Uses

Snap rivets

Properties

Uses

Glue dots

Properties

Uses

Zip-ties

Properties

Uses

Stitching

Properties

Uses

Note: When manufactured, different card elements and other materials can also be permanently laminated together using adhesive, heat sealing or wet bonding (pressed together while being made)

Temporary joints can be undone without damaging the material (are designed to be easily taken apart).

TEMPORARY LIGHTWEIGHT JOINING METHODS

Tabs & slots

Properties

Uses

Make sure closing tabs cannot be easily pulled undone

Velcro

Properties

Uses

Brass paper fasteners

Properties

Uses

Magnets

Properties

Uses

Rubber bands

Properties

Uses

Ribbons

Properties

Uses

String with eyelets

Properties

Uses

Photo corner stickers

Properties

Uses

Clips

Properties

Uses

These are not commonly used in graphic products, but may be useful when something needs to be moved or re-clipped by the user

Nylon bolts

Properties

Uses

ROTATING OR MOVING PARTS

Opening ‘mouth’

Properties

Uses

Slide-across tabs

Properties

Uses

Pop-up portions

Properties

Uses

Rotating disc

Properties

Uses

Other methods include a thumb tack embedded in stiff card

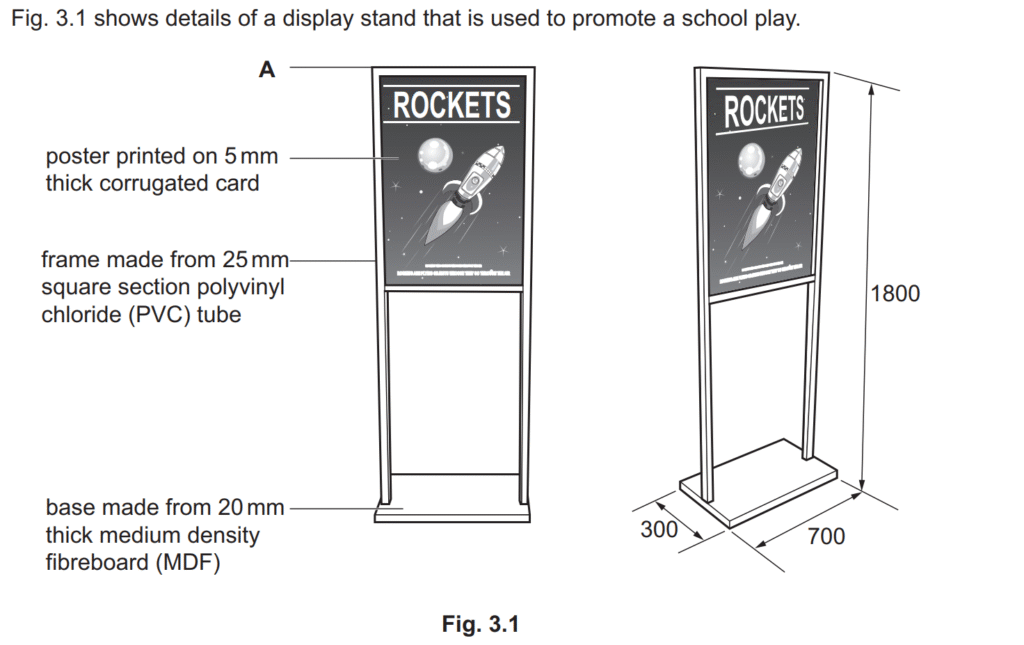

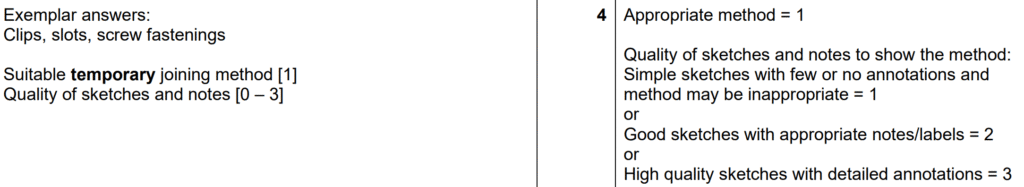

Sample examination questions (AS Design & Technology)

Examiner comment: Many very creative responses were seen to this question. Most candidates were able to show a temporary method of attaching the corrugated card poster to the PVC frame. The most common answers included the use of slots, clips, push fittings, magnets, Velcro and plastic screw fasteners. The quality of sketches and notes was usually of a high standard and sufficient to communicate the joining method. A small number of candidates incorrectly showed a permanent method of attaching the corrugated card poster to the PVC frame.

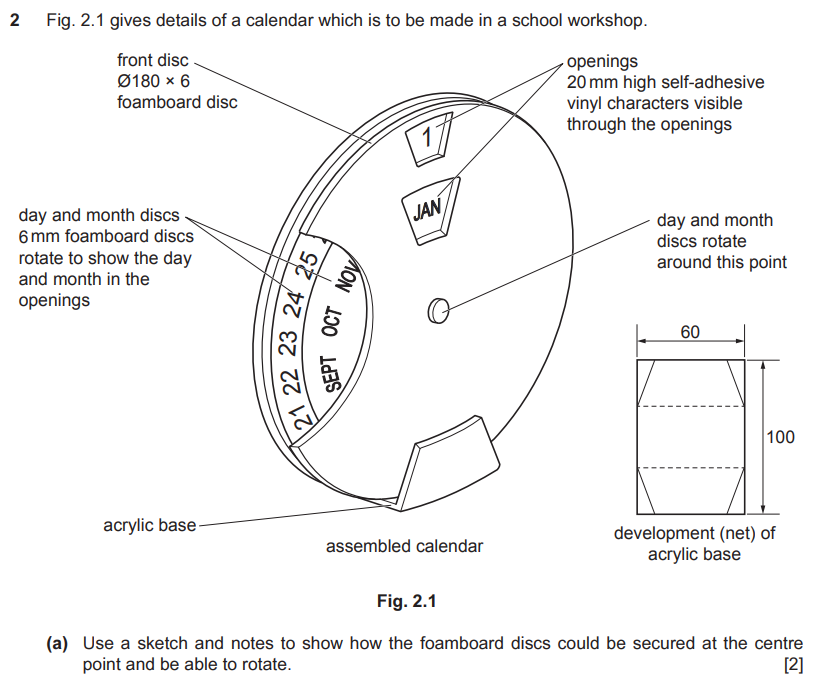

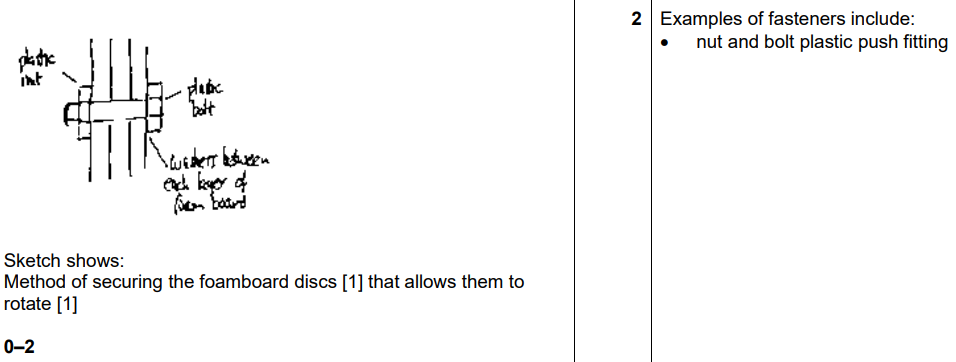

Examiner comment: Most candidates were able to correctly explain how the foamboard discs could be secured and made able to rotate.