Quality Control (QC) systems track the quality of a product to ensure consistency, meet customer expectations, and maintain brand standards.

- Involves checks on quality at various points during and after the production process (this may include destructive and non-destructive testing)

- Involves preset standards and tolerances (the acceptable level of variation)

- Gives customers an assurance of the quality of goods

- Often influenced by rules and regulations where products have to meet specific standards (such as use of non-toxic paints in children’s toys or electrical safety in product design or architectural design)

Quality control systems aim to lead to improved product design.

QUALITY ASSURANCE: Checks that are done during a manufacturing process to ensure the product meets the customers’ expectations.

0445 Design & Technology Syllabus, 2028-2030, Cambridge International Examinations

Examples of quality assurance (AA) checks used in the production of a product

These are checks that are made at each stage of production, and upon the made product, to ensure quality standards are set. These might include:

- Checking colour accuracy: Regular color matching checks against standardized color guides and ensuring color consistency across print runs.

- Print quality inspections: examining ink density and coverage, and identifying any printing defects like smudging, streaking, or banding.

- Design consistency checks: Using style guides to maintain brand consistency across products (rules for use of logos and colours etc).

- Ensuring proper bleed and trim settings.

- Creating and reviewing physical proofs before full production runs.

- Implementing systems to collect and analyze customer feedback.

Tools to improve quality control

Stencils

- A thin sheet of material with a design cut out of it

- Used by drawing inside, applying paint or ink through the cut-out areas onto a surface beneath

- The design is created by the negative space

- Typically used for repetitive designs or lettering

- Example: Spray-painting a logo onto multiple t-shirts

Templates

- A guide used to mark out similar shapes repeatedly

- Can be used to trace outlines or as a physical guide for cutting

- May have both positive and negative spaces

- Example: A plastic shape used to draw consistent curves in technical drawings

A template can be an efficient tool for creating multiple identical nets of a package by serving as a master design or pattern. If you need to cut something out a net from cardboard multiple times, you can create a template from card, MDF, or some other stiffer material and trace around it multiple times, ensuring consistency. This template would contain all the common elements and measurements for the package net, such as fold lines, cut lines, tabs, and dimensions. Not good for mass production, but useful if you need to make multiple copies yourself.

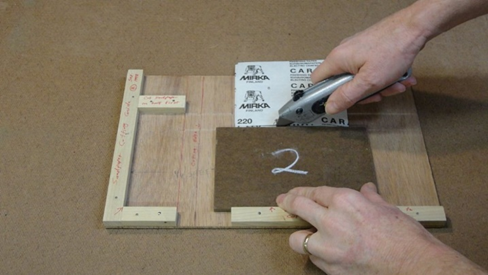

Jigs

- A tool, object or device (often custom made for a specific situation) that helps you hold a tool (or the work) in place or guide it as you perform a repetitive task like drilling or tapping holes, without you having to measure or guess each time.

- Increases accuracy, speeds up production, and maintains consistency in various production processes.

- Useful when creating multiple copies of a product by hand or when precision is crucial to the final appearance.

Formers and moulds

Various formers and moulders can be used to shape multiple items all the same, such as a former used in the vacuum forming process.

Computer aided design and manufacture (CAD/CAM)

See more about how CAM helps improve quality control here. Also consider how automated feedback in digital systems can be used to help improve quality control. Emerging technologies, such as virtual reality can also be used in the quality control process, creating simulations to help test the effectiveness of a product etc.

How can computers can enhance stock control and quality control?

- Real-time tracking and monitoring tracking stock levels across multiple locations, helping co-ordinate across different stores in a retail chain

- Barcode scanners allow shops to automatically update stock databases as items move in and out, eliminating manual counting errors and providing accurate up-to-date information

- Automated systems can monitor when stock gets low so people know when to order new supplies (optimising storage space)

- Algorithms can help forecast when stock will be needed – analysing historical sales data and trends (helping prevent waste)

- Automated systems can help inspect production lines – improving quality control (using sensors and automated scanning etc)

- Can track data about defects and returns – helping identify weaknesses and areas These computer-enhanced systems reduce human error, increase efficiency, lower costs, and ultimately improve customer satisfaction through better product availability and consistent quality.

Why manufacturers make use of standardised components

- Cost efficiency: The use of standardized components in graphic products significantly reduces manufacturing costs. As companies who produce standardised components typically produce larger volumes, this reduces prices, due to economies of scale. Consequently these can be far more cost effective, with different size / specification components able to be purchased as required at competitive prices. Rather than obscure unique components designed by one company, standardised items can typically be purchased multiple places, leading to competition between companies, driving prices down. For example, using standard-sized cardboard sheets for packaging allows manufacturers to produce different product lines more economically, ultimately passing these savings to customers. The use of standardized components also speeds up production times and reduces errors, resulting in faster delivery times for customers, ultimately reducing costs.

- Consistency of quality: Standardized components ensure consistent quality across product ranges. When manufacturers use standard paper sizes, ink formulations, and binding materials for publications, customers can rely on uniform quality regardless of when or where the product was produced. Standard components have established quality control processes and specifications. Customers benefit from components that have been thoroughly tested and proven reliable through widespread use in the industry. The manufacturer can specialise in their own particular area, rather than requiring speciality in multiple sub-areas. They may not have the equipment or expertise to make all the components. This improves accuracy, speed, confidence in product etc.

- Ease of replacement parts: Using standardized components makes replacement and maintenance more straightforward for customers due to the interchangeability of parts. Using standardised components means the sizes of things are designed around industry standards, which helps enormously with replacement parts, potentially boosting the reputation of the business. Replacing parts is also better for the environment as items can be fixed and used rather than discarded. Standardization also makes repairs more economical and accessible. For example, standard-sized poster frames, display unit components, and sign-mounting systems can be easily replaced without needing to replace entire systems when one part fails.

- Consistency across suppliers and regions: Standardized components ensure products work across different markets and regions. For instance, using standard ISO paper sizes means that packaging and printed materials can be used internationally without modification, benefiting customers who operate globally.

- Increased flexibility: Despite standardization, manufacturers can still offer customization options. Customers can personalize their products while benefiting from the reliability and cost-effectiveness of standard base components, such as using standard display frameworks with custom graphic panels. Furthermore, products that share common components can often be repurposed in different ways. For example, standard-sized display modules can be reconfigured for different promotional campaigns, providing better value and adaptability.

- Simplified manufacturing process: Standardization allows for more efficient inventory control and storage, as well as fewer steps in the production process. Retailers and distributors can more easily manage stock when dealing with standard-sized packaging and display units, delivering further cost savings. When pre-made components are used, there is often a reduced learning curve, as customers become familiar with standard components across different products, so staff require less training and can more efficiently set up and maintain displays.

- Supply chain reliability: Standard components are typically more readily available from multiple suppliers. This means customers face fewer delays and supply issues when they need replacements or additional components for graphic products. As stock is expensive to store, parts can often be ordered and supplied very rapidly – “just in time” (JIT) manufacturing, providing greater flexibility.

Total Quality Management (A2 students only)

- The benefits of introducing Total Quality Management (TQM) to a production process. (Total Quality Management involves applying quality assurance procedures at every stage of the production process.)

- The benefits of quality systems to the manufacturer and the consumer. – A2]

[Coming soon]