This article helps high school Design & Technology students familiarise themselves with printing methods and surface treatments suitable for use in graphic products. It concludes with sample examination questions from the Cambridge IGCSE and AS/A Level syllabus.

PRINTING METHODS

Digital Printers

Description

Uses

Plotter printers

Description

Uses

A plotter cutter prints and cuts. See more ways to cut paper and card.

Letterpress printing

Description

Uses

Flexography

Description

Uses

Offset lithography

Description

Uses

Gravure

Description

Uses

Photocopying

Description

Uses

Screen printing

Description

Uses

Block printing / lino cut / wood cut

Description

Uses

Dry transfer

Description

Uses

These are like rub-on stickers

Sublimation printing

Description

Uses

A2 students only

Sublimation = when a solid transforms into a gas without becoming liquid first

Pad printing

Description

Uses

A2 students only

Colour separation during printing

A2 students only

Different printing methods have different ways of applying colour. For example, single colour printing involves using just one colour ink. Digital inkjet printing, on the other hand, applies all colours simultaneously. However, many traditional printing methods, like offset lithography, screen printing, and flexography, apply coloura individually.

Colour separation is the process of breaking down a full-color image into individual color components so each can be printed separately.

In CMYK printing, an image is divided into 4 separate layers – cyan (blue-green), magenta (pinkish-red), yellow, and black. These are the subtractive primary colours + black, which can be combined to make all the other colours. Each color is applied one layer at a time in precise alignment (tiny dots that overlap each other slightly). When these overlap and combine in different amounts, they create all the other colors you see in the final image. Instead of printing “green” the printer lays down cyan + yellow in the same spot, and your eye sees green.

Without colour separation, printers would need a separate ink pre-mixed for each color in the image, which would be impractical and expensive.

Advantages of colour separation during printing:

- Enables full-color printing using just 4 inks (Cyan, Magenta, Yellow, Black)

- Cost-effective for reproducing thousands of colors

Disadvantages of colour separation during printing:

- Requires precise alignment of each colour layer – misregistration causes blurry or offset images

- Difficult to match certain vibrant colors (bright oranges, greens, metallics)

- Can be colour variations between what you see on screen and final print (because screens use RGB colours – represented by mixing red, green, and blue light)

Types of surface treatments used for paper and card

SURFACE TREATMENTS

Embossing

Description

Uses

Laminated layers

Description

Uses

Lamination = thin layers bonded or glued together

Laminating machine

Description

Uses

Varnish

Description

Uses

Varnish is also commonly used to finish wooden products

UV lacquer

Description

Uses

Note: some students mistakenly think UV lacquer offers protection against UV light, however it does not: it cures/sets using UV light

Hot foil blocking

Description

Uses

This process is also known as hot foil stamping

Why surface treatments are used in graphic products

- Protection against physical damage (i.e. UV lacquer can make a book cover more resilient, extending lifespan – better for the environment, as fewer replacements needed / less waste)

- Moisture resistance (food packaging often incorporates water-resistant lamination / PE coating to maintain structural integrity and prevent deterioration when exposed to condensation or spillage – can also allow a surface to be wiped clean, or written on with a whiteboard marker and wiped-off)

- Food safety compliance (can help to ensure packaging meets food safety regulations, with food-grade coatings, such as a PE coating, creating barriers between food products and printed materials, preventing ink migration and contamination)

- Enhanced visual appeal (decorative finishes such as strategic use of matt and gloss finishes or metallic foil can make a product look expensive / appealing)

- Improved tactile qualities (these not only stimulate interest, but can provide important cues for visually impaired users)

- Chemical resistance (protecting against chemical exposure or staining from spills)

Sample exam questions relating to printing methods and surface treatments

AS Design & Technology

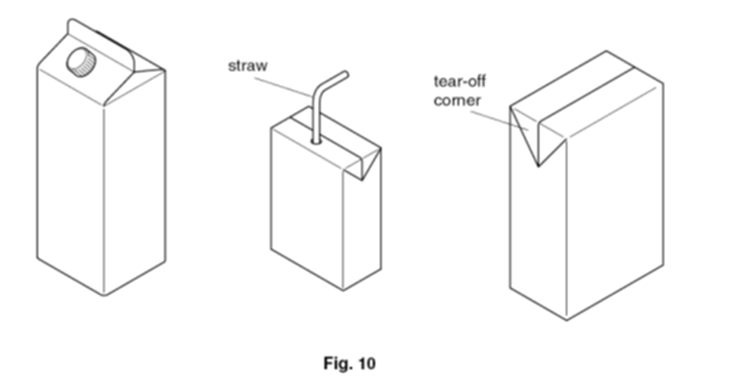

Fig. 10 shows three cartons which are used to hold fruit juice. The cartons are made from card which has been laminated with polythene.

Explain why the card has been laminated with polythene. [2]

Explanation (0-2) e.g.

- To make the card waterproof (so it doesn’t leak or become soggy)

- To provide a more hygienic internal surface, so it doesn’t absorb the juice

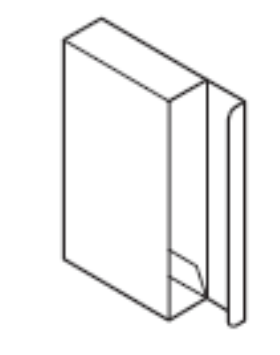

The following box is made from card which has been coated with UV lacquer. The box has one opening flap.

Give two reasons why an ultraviolet (UV) lacquer has been applied to the box. [2]

Gives shiny surface (aesthetic improvement)

Protects surface.

Any two relevant answers (2×1)

Examiner comment

Very few correct answers were seen. Many candidates thought that ultraviolet lacquer would prevent the tape from being damaged by ultraviolet rays from the sun. Correct answers needed to explain that the application of the lacquer protected the card by giving it a very smooth, high gloss finish

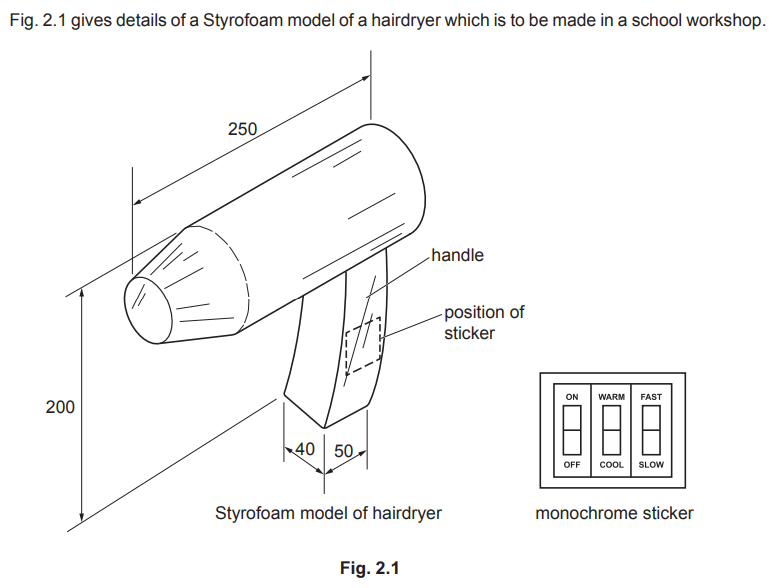

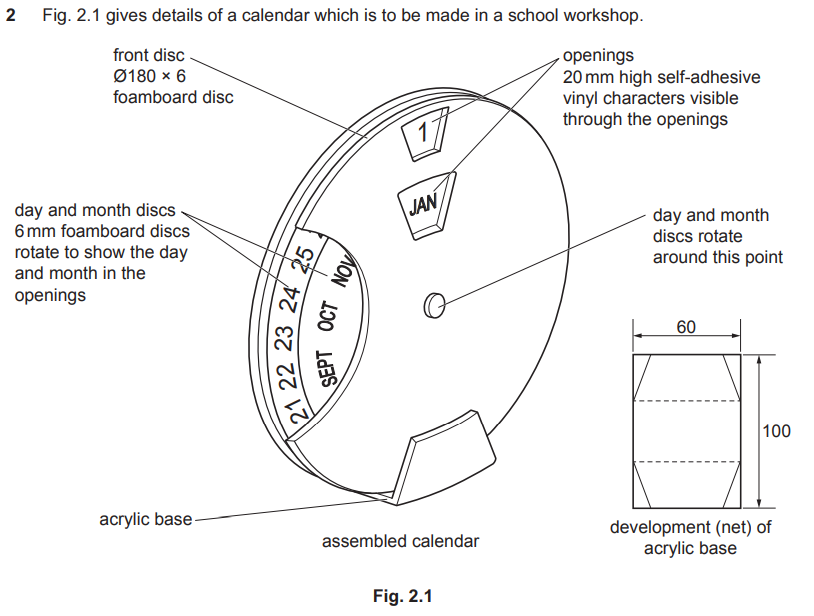

Examiner comment: Candidates had a good understanding of how to make and apply the monochrome sticker. The use of various design packages to design on computer and then print in batches was a very popular response.

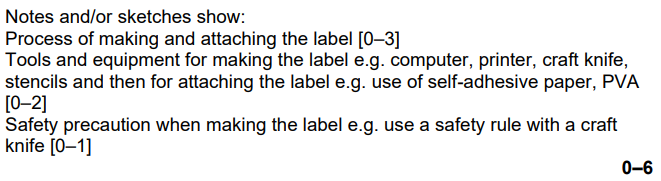

Examiner comment: Candidates had a good understanding of how to make the paper label and attach it to the package. The use of various design packages to design on computer and then print in batches was a very popular response.

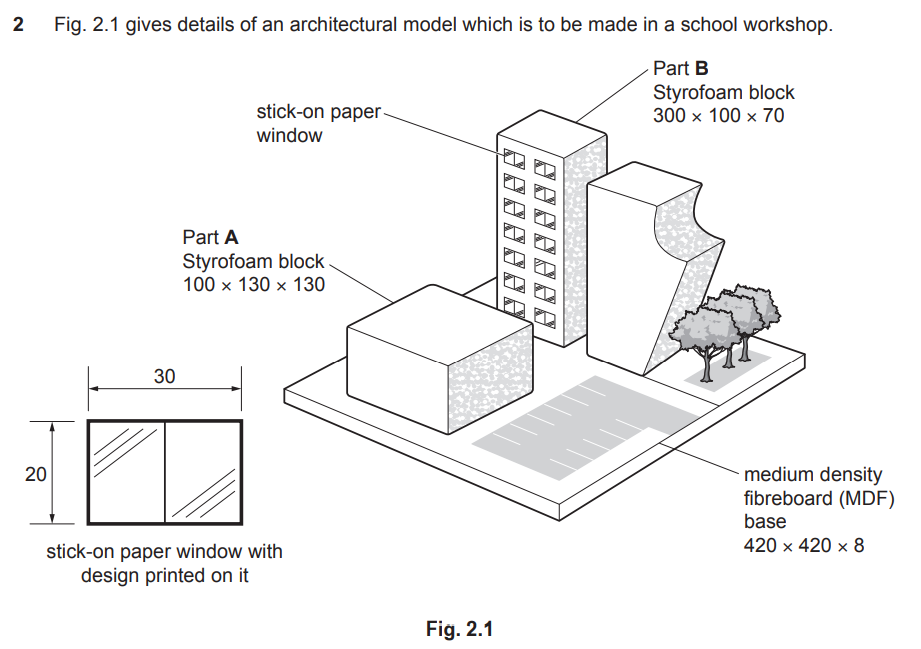

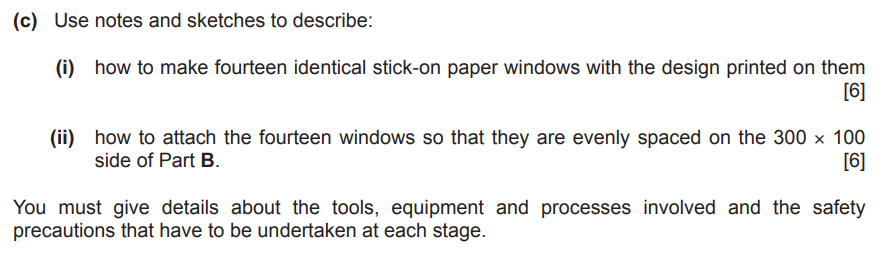

Examiner comment: Candidates had a good understanding of how to make fourteen identical stick-on paper windows with CAD/CAM often used. Occasionally candidates did not design the graphic on the windowpanes.

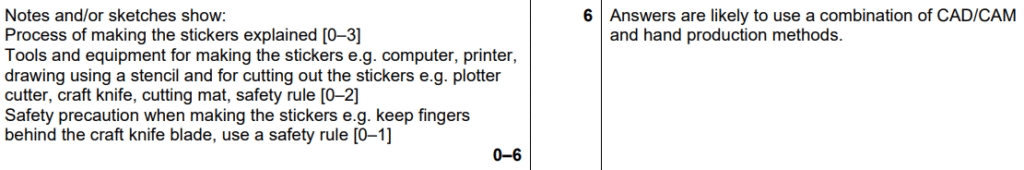

Examiner comment: Candidates gave a wide variety of answers to this question. Stronger candidates either made a stencil or clearly explained how to measure and mark out the even spacing of the fourteen windows. However, some candidates did not give such levels of detail and found the question challenging.

Examiner comment: Candidates had a reasonable understanding of how to make and apply the self-adhesive vinyl characters including the use of tools and equipment as well as CAD/CAM. Safety precautions were often omitted.