Understanding the cost of a product throughout its lifecycle is crucial for establishing whether a product is commercially viable and able to be sold for a profit. Cost considerations extend far beyond the initial manufacturing process and encompass everything from research and development to eventual disposal. This guide helps students evaluate the financial implications at each stage of a product lifecycle.

Costs during research and planning

- What research and development costs were involved? Does collection of this data require expensive research or sophisticated software?

- Can the idea be modelled and prototyped in a cost-effective way?

Costs during construction

- What is the unit cost of each material?

- Are there bulk purchasing opportunities?

- Does construction require expensive, specialized equipment or tools?

- What are the labour costs and skill requirements?

- Is batch or mass production utilised to reduce the cost of production overall? Could automation reduce long-term manufacturing costs? Are there high setup costs for production runs?

- What quality control measures are needed (quality inspections, jigs, templates) and how do these save costs (such as by reducing errors and increasing production speed)?

- Is there significant material waste during manufacturing? Are there opportunities to reduce material waste through altering the design?

- Does the design utilise standard sheet sizes and components?

- Can the design be simplified to reduce costs?

- Could alternative materials lower costs without compromising quality?

- Are certification costs involved?

Costs during transport and shipping

- How do size and weight affect shipping costs?

- Are there import/export fees to consider?

- Could the product be designed to reduce shipping costs, such as by making the product stackable?

Operational costs

- What are the ongoing operational costs (energy, consumables)?

- Are there subscriptions or service fees?

- Do high operating costs affect sales?

Costs during maintenance and repair

- How frequently do parts need replacement? What is the cost of spare parts? Is maintenance expensive? Are specialized repair tools needed?

- Are specialized cleaning products required?

- Could modular design reduce repair costs (such as by integrating standard components, so that they can be easily replaced without required custom design)?

- Could maintenance costs affect the product’s competitiveness?

- Are repairs cost-effective, or do consumers normally dispose of the product and buy another?

Costs during disposal

- Are there special disposal fees for any materials?

- What recycling costs are involved?

- Could design changes reduce disposal costs?

- Are there any recovery values from materials – so that materials can be onsold or upcycled for another purpose?

- Could disposal costs affect the initial purchase decision?

Retail price

- How do all of these lifecycle costs affect the final retail price?

- Is the product a premium, high-end product, budget-friendly, or somewhere in the middle?

- Is the product affordable for its intended target market?

- Are there different pricing levels to cater to different segments of the target market?

- Is it an essential or luxury product? How do changes in the economy influence sales? (For example, even when times are tough, people still purchase food and other essentials, let the sale of luxury goods often dwindles.) Is the product recession-resistant? Does the product’s value proposition change in different economic conditions?

- Could a more complex design be off-set by a higher sale price?

- Could a cheaper construction price create a larger profit margin?

- How do costs compare with competitor products?

- How might future regulatory changes affect costs?

Sample examination questions (AS Design & Technology)

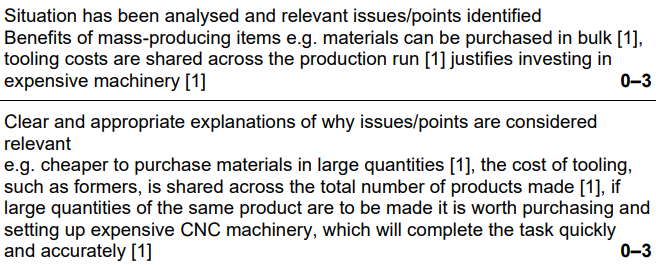

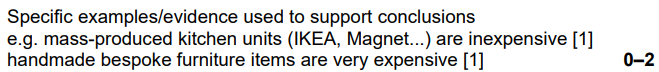

Discuss how manufacturers of mass‑produced products are able to reduce unit production costs.

Examiner comment: Candidates gave a broad range of well thought out answers showing their understanding of how manufacturers of mass-produced products can reduce unit costs. Materials being bulk purchased, sharing tooling costs across many products, automation and the reduction in labour costs were often well communicated. Lego was a very well communicated example. Examples were not always given.