‘Flat packed’ refers to a product that is sold unassembled, with all major components lying in flat sheet form in a box. Customer has to do simple assembly.

- Cheaper to post, because takes up less space;

- Manufacturer saves money, because doesn’t have to assemble products themselves

- Product can often be purchased for less (manufacturer does not have to assemble, and generally passes savings onto the customer, to encourage them to purchase the product);

- Less likely to get damaged while transported (i.e. packaging would crush if assembled) – offers protecting during transit – better quality control (QC). Allows large or crushable items to be shipped more easily (for example, much better for packaging to be sent flat packed).Saves on storage space;

- Often easier for customers to transport items home (easier to fit in cars and through narrow doorways and tight-fitting spaces).

- Can be frustrating and time-consuming for customer to construct the item, particularly if instructions are unclear to follow. Can require a reasonable amount of strength or technical proficiency (elderly customers may find assembly of heavy components difficult). Assembly needs to be simple and well explained.

- The product can appear ‘cheaper’ and lower quality than ready made products, which have the entire finishing process under the control of the manufacturer.

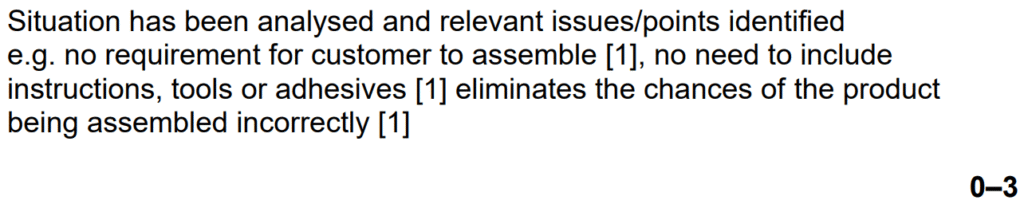

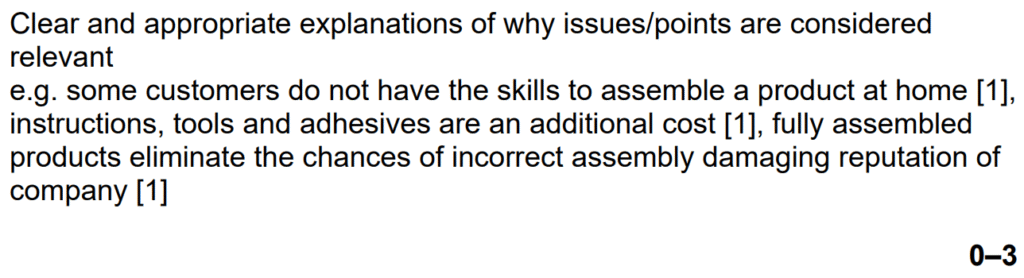

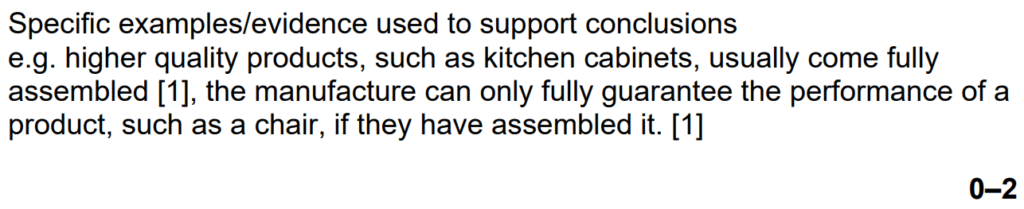

Discuss why manufacturers of furniture, such as a bathroom cabinet, produce products that are fully assembled with permanent fixings.

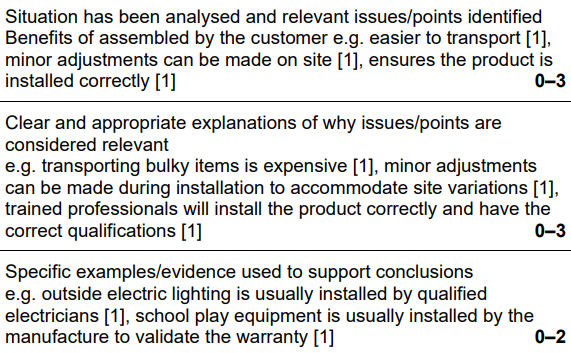

Discuss why some products are designed to be assembled by the customer

Examiner comment: Candidates gave a broad range of answers relating to their understanding of why many products are designed to be assembled by the customer. Difficulties with transporting large items and saving the manufacturer time and money to assemble products were often communicated well. Thorough

explanations and examples were not always given.