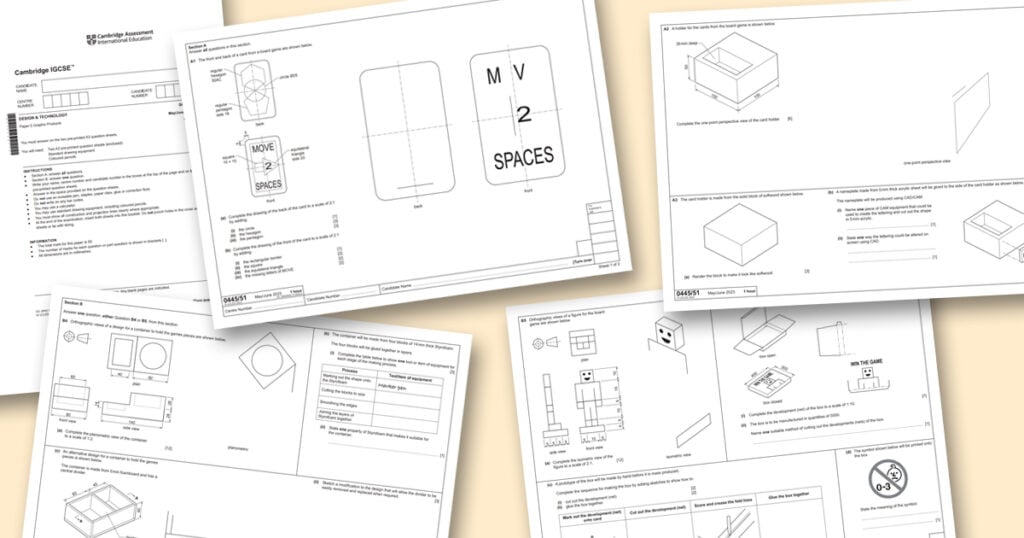

This article summarises the topics that should be revised for Cambridge IGCSE Design & Technology, Paper 5: Graphic Products (0445/05). This exam involves using a drawing board to produce measured technical drawings, charts, and diagrams, as well as short-answer written questions.

- This paper is 1 hour long

- 50 marks are available

- Worth 25% of your final mark

- Section A: answer ALL questions (both sides of the first A3 sheet)

- Section B: answer ONE question (one side of the second A3 sheet)

Please note: Paper 5 also tests aspects of the common core syllabus examined for Paper 1. You should also study the revision notes for Paper 1: Product Design.

Equipment to bring to the exam

- HB pencil (plus a backup pencil)

- Pencil sharpener

- Eraser

- Set squares (30°/60° and 45°/45°)

- Good quality compass

- Calculator (you may have to calculate scales etc)

- Colouring pencils

- Thick dark pencil for thick and thin line technique (or a black pen, but be careful because it may bleed through the page)

- Protractor (in case you need to check any angles)

- Blue / black pens (for written answers)

Topics to Revise for Paper 5: Graphic Products

These revision notes are based on the specialist Graphic Product content in the IGCSE Design & Technology syllabus.

You should be able to understand and use:

- British Standards for drawings, including how to use common line types (such as construction lines, hidden detail lines, centre lines), dimensioning rules, and scales (such as 1:5)

- Orthographic projection, recognising both first angle and third angle symbols

- Isometric, including isometric circles, arcs, and other curves

- Planometric views at 45° × 45° and 60° × 30°, including circles and arcs

- Estimated one-point perspective and two-point perspective, including the use of perspective grids

- Sectional drawings (including whole, part, revolved and removed sections), hatching guidelines, and rules for sections involving bolts, washers, screws, and pins

- Exploded drawings of components along one axis

- Assembly drawings where parts are assembled into a single drawing, often with a parts list

- Geometric construction of regular and irregular shapes, including triangles, quadrilaterals, pentagons, hexagons (AF and AC), octagons (AF and AC), and n-sided polygons

- Bisect angles, bisect lines, sub-divide and proportionally divide lines

- Circles (finding the centre of circles and curves), tangents, and tangential arcs

- Developments (nets) of cubes, prisms, cylinders and cones, including simple truncations

- Ellipses

- Enlarge/reduce a shape to fit within a given size or location, including applying one-point perspective to enlarge/reduce a shape or line to a given scale or ratio

- Be familiar with drafting aids such as set squares, T-squares, technical pens, flow chart templates, lettering and other stencils, radius aids, and flexicurves

- Thick and thin line technique

- Rendering techniques to represent 3D form, texture and surface quality of materials

- Lettering styles, letter spacing, stencils, dry transfer methods, and computer generated lettering, selecting font style suitable for content, purpose and user

- Understand and interpret written, visual and tabular data, presenting these ideas in graphical format. This might involve interpreting or producing diagrams, line graphs, bar charts, pie graphs, gantt charts, flow charts, sequence drawings (like cartoon strips that show a process), and so on

- Standardised signs and symbols including warning and safety symbols

- Identify materials that can be recycled and those that cannot, including the use of recycling symbols on products

- Printing methods

- Materials knowledge: paper and lightweight boards, plastics used in graphic products,

Styrofoam and foam board, self-adhesive vinyl, polymorph - Shape memory alloy (SMA) and thermochromics

- Temporary and permanent joints in graphic products using adhesives

- Joining methods including slots, arrow-tabs and flaps, reinforcing methods, fold-over locking flaps and lock rudder flaps used in packaging and display

- Use of a computer to research shapes, images and letter fonts

- Awareness that digital images can be captured and stored on a computer

- Awareness of the use of a computer to alter the size and area of suitable

shapes, images and letters - Have an awareness and understanding of how computers can enhance stock control and quality control

- Awareness of the use of a computer aided design (CAD) and computer aided manufacturing (CAM)

- Identify the features of a control system in terms of input devices, processing elements, output devices and feedback

- Awareness that a range of computer output devices can be used to give hard copy or a cut profile suitable for application to a graphic product (for example, the use of a digital printer to print a poster, a plotter cutter to print and cut a packaging net, or a laser cutter to cut out and/or engrave)

- Understand the processes of forming methods such as blow moulding and vacuum forming to create blister packaging

- Understand the commercial processes used to cut, crease (score) and shape materials for quantity manufacture of graphic products

Reminders: Monitor time carefully. You have 1 hour to complete the exam. There are 50 marks. Section A is worth 25 marks. Section B is worth 25 marks. This means you should aim to spend roughly 15 minutes on the first side, 15 minutes of the second side, and leave the remaining half hour for Section B (the one side you choose).

NAME BOTH SHEETS OF YOUR ANSWER PAPER! (Make sure all places to enter your name are filled in)

Don’t forget to revise for Paper 1: Product Design too!