Design & Technology students must be familiar with a range of temporary and permanent joining methods for timber or manufactured boards. This article helps students revise this information and concludes with sample examination questions from the Cambridge AS/A Level syllabus.

Advantages of joining timber using temporary joining methods

- Can be disassembled easily storage and transportation (great for flat-pack furniture)

- Creates flexible joints that allows wood to shrink / expand with temperature changes and can accommodate some movement without breaking

- Can often be put together with basic tools (or slotted together without any tools at all) – easier for consumers

- Can be better for environment as fewer components / materials needed and easier to take apart to replace / repair components (less waste)

TEMPORARY JOINING METHODS FOR TIMBER

Slot together

Description

Uses

Nails

Description

Uses

Screws

Description

Uses

Nuts and bolts

Description

Uses

Knock-down fittings

Description

Uses

Brackets

Description

Uses

Types of holes (in metal or timber)

Clearance holes are is slightly wider than the item passing through it, so the bar, bolt, pin, or screw to pass through freely without binding (the diameter of the hole is larger than the fastener’s outer diameter). Clearance is the intentional space or gap between two connecting parts or components.

Blind holes don’t go all the way through the material – they have a bottom (if you look inside them they are dark) – so the rod or pin etc cannot pass through it.

Internally threaded holes have thread cut into their interior walls, so something can be screwed in. Threaded holes are originally drilled a bit smaller than the inserting bolt, and then a ‘tap’ is used to cut the threads. (Rods, bolts, or pipes with threads on the outside are cut using a threading die – this is explained in more detail in the article about shaping metal.)

Countersunk hole: a conical or angled recess machined into the surface to fit the head of a countersunk screw.

Counterbored hole: a cylindrical recess machined into the surface around the hole opening. This accommodates hex bolt heads, washers, or other hardware, allowing them to sit below the surface level. Unlike countersunk holes, the recess has straight vertical sides.

Pilot hole: a thin initial hole used a guide. This could be used to drive a screw in straight (and more easily), or to help ensure a large hole is drilled in the right spot.

Advantages of permanent timber joining methods

- More strong and rigid

- Typically more durable

- Can be higher quality items (produced by the manufacturer / maker)

PERMANENT JOINING METHODS

Glued joints

Properties

Uses

When joining timber, bracing and other methods of reinforcing and strengthening structures should be considered.

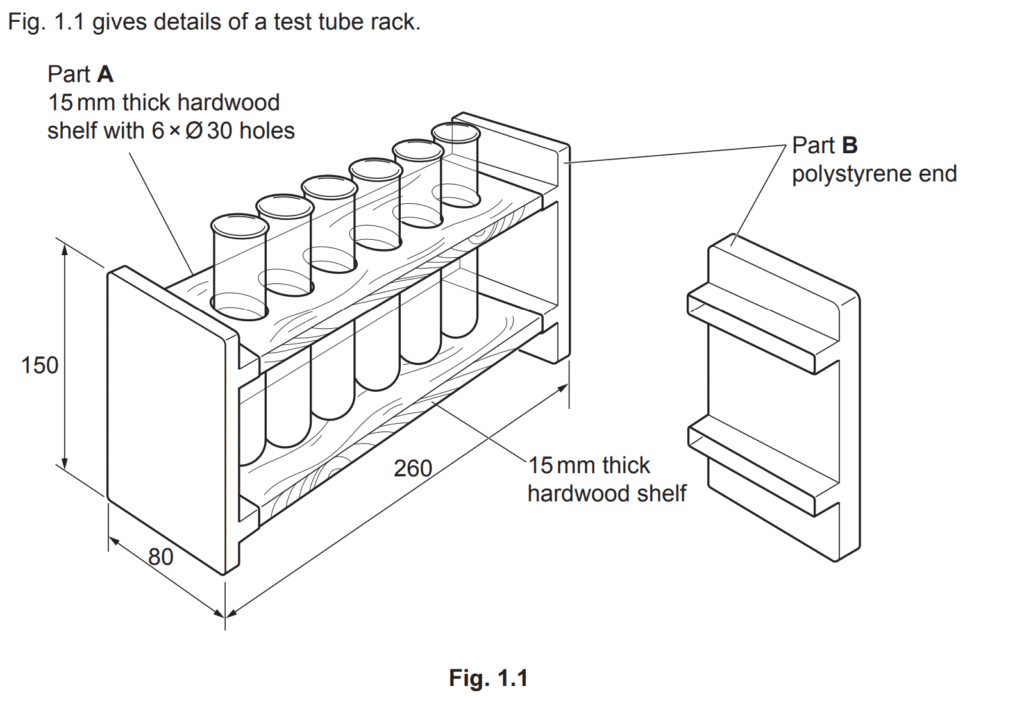

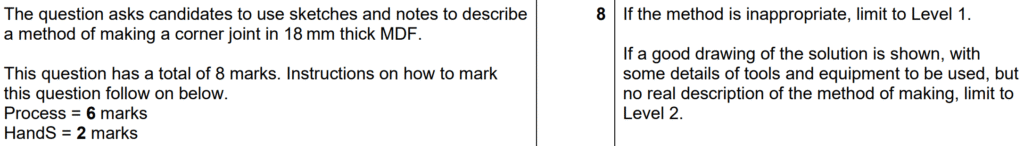

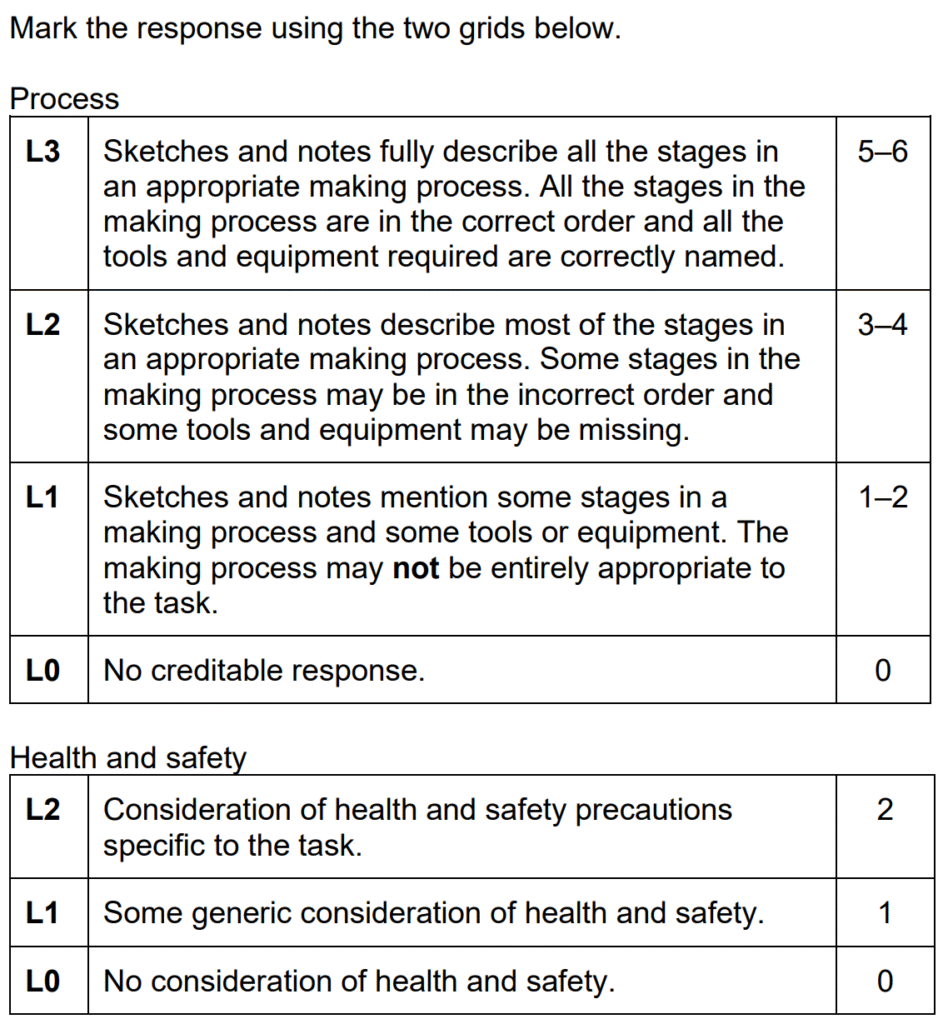

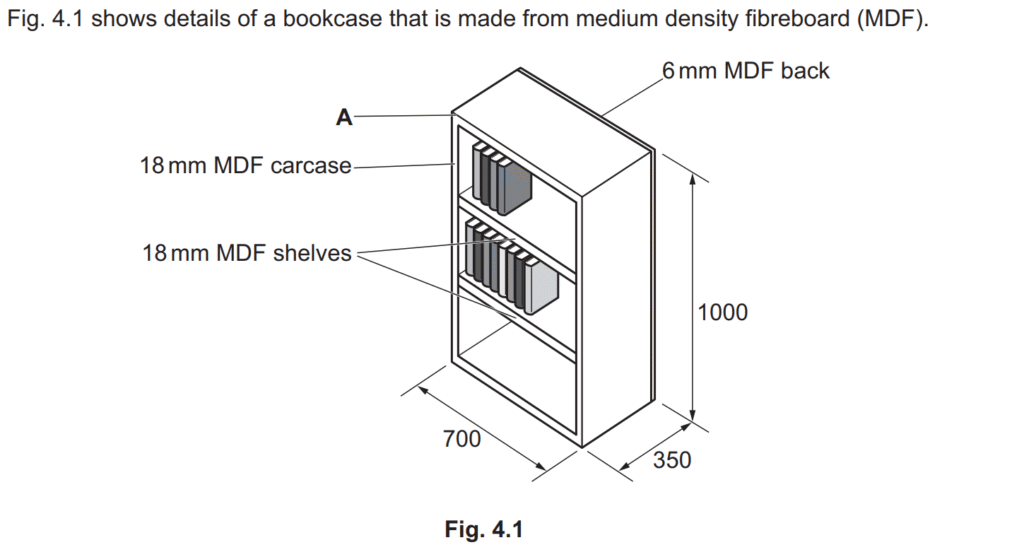

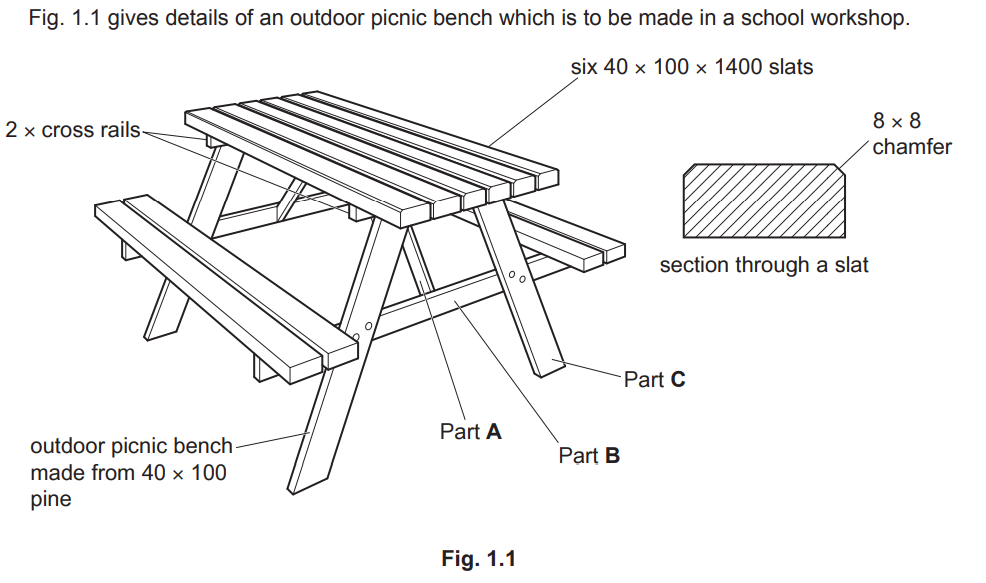

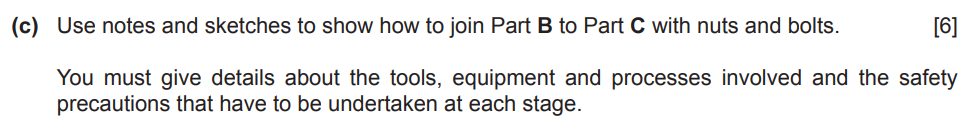

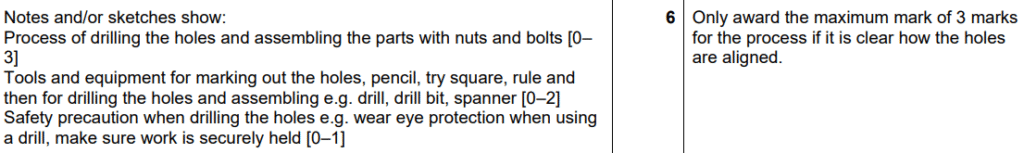

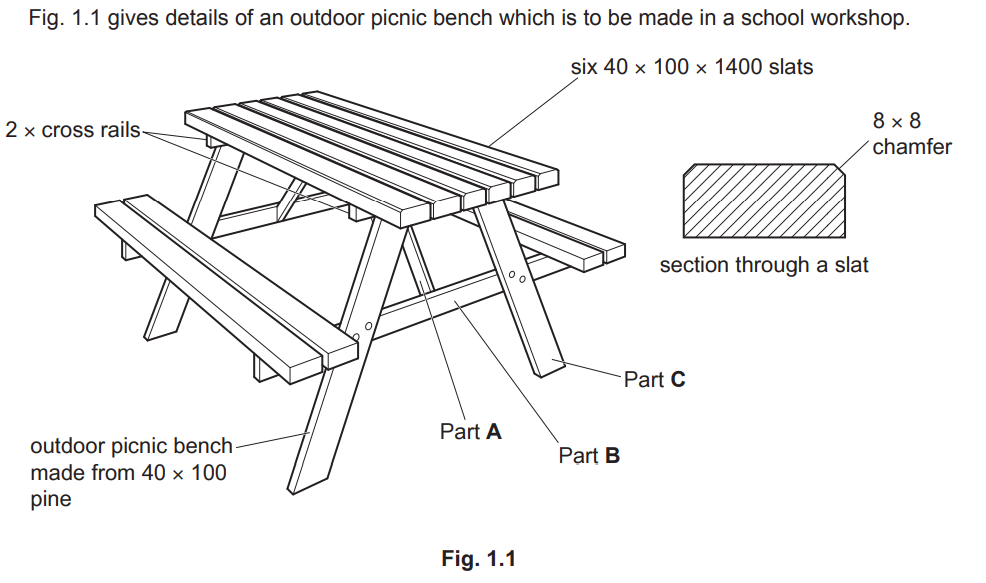

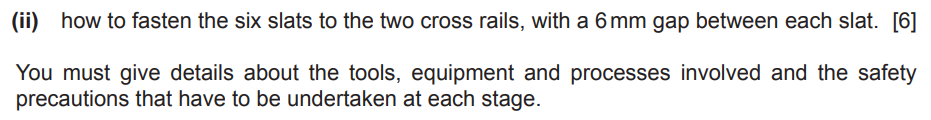

Sample examination questions (AS Design & Technology)

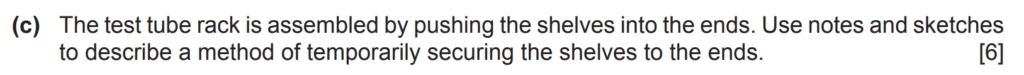

Examiner comment: Many excellent responses were seen to this question. Solutions for joining the corner of the bookcase included dowel joints, rebate joints, finger joints, mitre joints, dovetail joints and the use of nails and screws. In weaker responses, the sketches and notes only showed the joint, and not the method of making the joint. Where the method of making the joint was shown, this was usually through a series of steps that included details of tools, equipment and processes to be used. Some candidates did not include details of safety precautions to be undertaken during the making of the joint or only included superficial details of the Personal Protective Equipment (PPE) that would be

required, rather than linking the use to a specific stage in the making process.

Note: see a sample answer to this question on the production processes page.

Examiner comment: Many excellent responses were seen to this question. Methods of making the shelf height adjustable were dowels, pegs, slots and a range of brackets. Some candidates focused on making the shelf adjustable to different heights, for example at 150 mm intervals, and others on making the shelf adjustable to any height. In weaker responses, the sketches and notes only showed the adjustment method and not the method of making it. Where the method of making the adjustment method was included, this was usually shown through a series of steps that included details of tools, equipment and processes to be used. Some candidates did not include details of safety precautions to be undertaken during the making of the height adjustment method or only included

superficial details of the Personal Protective Equipment (PPE) that would be required, rather than linking the use to a specific stage in the making process.

Examiner comment: Candidates found being able to show the difference between clearance, blind and internally threaded holes very challenging.

Examiner comment: This was a very well answered question with candidates demonstrating a good knowledge of how to mark out, drill and join Part B to Part C. There were some very good responses that detailed how using a jig or clamping the two parts enabled a more accurate outcome.

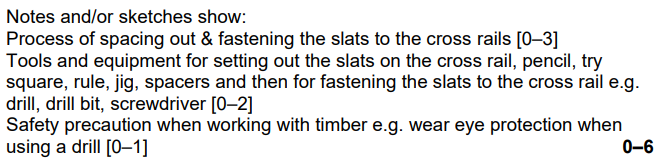

Examiner comment: This question was usually answered well with candidates understanding the steps necessary to mark out and fasten the six slats to the cross rails. There were some excellent responses that detailed the use of spacers or a jig to set out the 6mm gap.