Cambridge AS / A Level Design & Technology students must understand how emerging technologies, such as 3D printing, robotics, artificial intelligence (AI), and virtual reality (VR) impact on designing and manufacturing products. This article summarises these ideas.

Emerging technologies include:

- Cutting-edge manufacturing tools (such as 3D printers)

- New manufacturing inventions (i.e. biomanufacturing processes involve growing products using living organisms, such as mycelium leather, which is a leather-like material grown by fungi, bioplastics such as PHB made by bacteria, or bio-concrete, which incorporates bacteria that produce limestone and can self-heal cracks in the concrete)

- Rapidly developing technologies (like AI or VR)

Emerging technologies are often in early stages of adoption and characterised by rapid evolution and may have transformative potential.

Evolution in this context refers to the gradual development and improvement of technologies over time through incremental changes and refinements. Rapid evolution occurs when these changes happen at an accelerated pace, often within months or years rather than decades – as we are seeing with AI.

Keeping up to date with knowledge about scientific developments and advancements in technology can help designers create innovative products and inventions.

An invention in design and technology refers to the creation of a completely new product, manufacturing process, or solution that didn’t exist before. Some inventions are protected by a patent (a legal document that says the inventor holds the exclusive rights to make, use, or sell their invention for a specified time – protecting the idea from theft by others).

Innovation = creative problem-solving, and generating clever and valuable design solutions to meet human needs. It may involve combining existing technologies, materials, or ideas in new ways to solve problems or improve functionality. For example, adding wheels to luggage, combining a phone with a camera, or using existing materials in new applications.

INNOVATION: The use of new methods or ideas to generate or develop design proposal.

0445 Design & Technology Syllabus, 2028-2030, Cambridge International Examinations

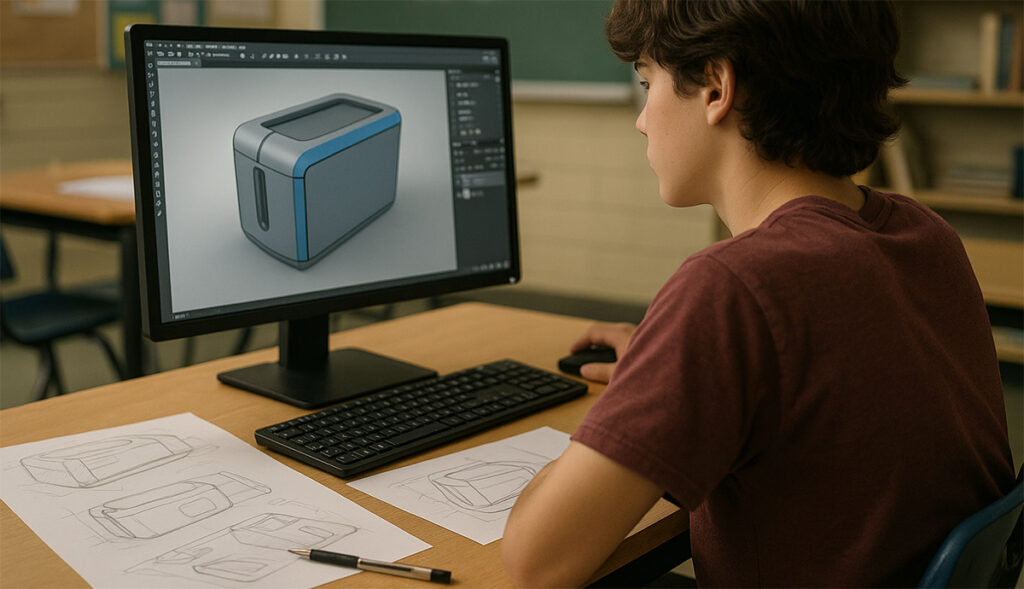

Rapid prototyping is the process of quickly creating physical models or prototypes using digital fabrication technologies like 3D printing, laser cutting, or CNC machining (very helpful in encouraging an iterative design process).

Rapid manufacturing is the process of directly producing finished, end-use products from digital files using similar technologies, but with production-grade materials and high quality control standards.

The impact of 3D printers upon design and manufacturing

- Prototypes can be created far faster than ever before – rapid prototyping

- Designers can quickly evaluate and test designs as part of the iterative design process

- Products can change quickly in response to customer feedback or market demands

- Often far cheaper than traditional methods of creation, as minimal set-up costs: no specialised moulds, dies, individual tools or jigs are not needed (however the cost of purchasing the 3D printer itself is substantial) – this can make even small production runs cost-effective, including those which wouldn’t normally be viable, and make testing new ideas feasible and less financially risky

- Products can be made ‘on-demand‘ reducing storage costs and the need to store stock

- Can integrate personalised elements far more easily – mass customisation becomes far more economically viable, allowing the product to cater to niche markets or those with unique needs

- Can produce complex geometries that might be beyond craftspeople, traditional machinery, or be very expensive using conventional methods

- Manufacturing can occur closer to customers, reducing shipping times. For example, when people purchase a book published through Amazon from New Zealand, the book is often printed-on-demand in Australia, and then shipped out to customers then and there (no warehousing / storage necessary). Similar arrangements could also take place with 3D printed products.

- May reduces waste through more precise material usage – however careful planning of ‘supports’ in 3D printing is necessary.

- Downside: May encourage the usage of significantly more plastic – products that might previously have been crafted out of sustainably grown timber might be replaced with plastic, which has negative environmental consequences (although more environmentally friendly plastics, such as PLA – plant based and biodegradable – are being developed).

The impact of robotics on design & manufacturing

Automation has been developing in factories since the Industrial Revolution, with machinery being used to complete tasks previously done by humans. Automated machines are programmed to carry out a procedure multiple times, eg repeatedly creating the shape of a car door using a press, to improve production time.

New and emerging technologies, BBC BiteSize

Robotics involves machines that can sense their environment, process information, and take physical actions in the world. Many robots operate using relatively simple control algorithms, pre-programmed behaviors, or basic feedback loops, and some may use AI.

Ways in which robotics impacts the design and manufacture of products:

- Improved precision and consistency, ensuring that every product meets the exact same specifications, eliminating human error and reducing defective products.

- Increased speed and efficiency – unlike human workers, robotic systems don’t get tired and can work continuously without breaks, dramatically increasing production rates – resulting in cheaper prices for consumers.

- Minimises risk to humans, as robots can handle dangerous tasks, such as those involving toxic materials or extreme temperatures.

- Although has very high initial investment costs, long-term cost per unit is low (reduced labour costs, reduced legal costs due to injuries, reduced product recalls, and minimal waste of materials)

- Products can be designed specifically for robotic assembly, with standardised components and modular design that work well with robot capabilities.

- Robots equipped with scanners can inspect products and provide real-time feedback, helping to ensure quality control.

- Can displace human jobs, especially low-skill roles, although it may open up other opportunities – such as jobs for experts repairing / servicing the machines.

The impact of AI on design and manufacturing

Ways in which Artificial Intelligence impacts the design and manufacture of products:

- Allows immediate visualisation of ideas without the needing to hire a design expert –likely to rapidly displace many jobs.

- Can speed up research phases of a project, analyzing customer feedback, and market trends.

- Can help rapidly generate thousands of design variations based upon specific criteria, including solutions humans might not have thought of.

- Can monitor systems using data from sensors (vibration patterns, temperature variations etc) to predict when machines will need maintenance before they fail, extending equipment life.

- Can assist with quality control, inspecting products at speeds and accuracy levels impossible for human inspectors, detecting microscopic defects in real time.

- AI can enable robots to perform complex tasks that previously required human dexterity and decision-making.

Virtual Reality

Ways in which virtual reality and augmented reality impacts the design and manufacture of products:

- Can simulate new products so that designs can be immediately understood and visualised by clients and other stakeholders who may be unable to read orthographic drawings, avoiding miscommunication. These can be great marketing tools used by those who are trying to seek funding for projects, etc.

- Allows viewers to experience a sense of ‘serial vision‘ (the changing sequential viewpoints as you move through 3D architectural spaces), appreciating designed spaces and 3D forms in a way that is not possible from flat, two-dimensional drawings.

- Can simulate weather conditions, mimicking rainfall, or lighting conditions at different times of day, detecting issues to do with shadows, glare, and so on, allowing the designer to carry out complex testing before a single product is made, and quickly identify errors and flaws in designs.

- Some simulation software has complex physics-based models built in, allowing stress testing, thermal analysis, and other simulated tests.

- Can be used to create virtual training videos, showing how new systems, designs, or technologies are to be used, improving the safety of products.

- Simulations can be fully rendered or ‘wire-frame’ (showing all edges of forms as a black line, with no tone or colour).

The video below by UrbanCGI illustrates how digital simulations can be used to create 3D virtual training experiences:

Web / app integrations / digital displays

- Many products now incorporate digital displays

- Methods of remote activation: QR codes, voice activation, app activation

Microelectronic integrated circuits (commonly called “chips” or “microchips”) are tiny electronic circuits that contain thousands to billions of microscopic components. These have allowed the development of increasingly powerful, portable computerised products.

Wider issues relating to emerging technologies

- Unequal access – individuals, schools, companies, and countries may have vastly different exposure to technologies like 3D printers, robotics, or CAD software on a daily basis – this means some designers may develop confidence in these tools while others may not

- Different individuals have different values – some may emphasise craftsman ship and hand-made products over technological innovation.

- Some people are very fearful of where AI is leading and others are deeply resentful about the disruption to human jobs, boycotting the use of any AI products (differing viewpoints within society.

Sample Exam Question (AS)

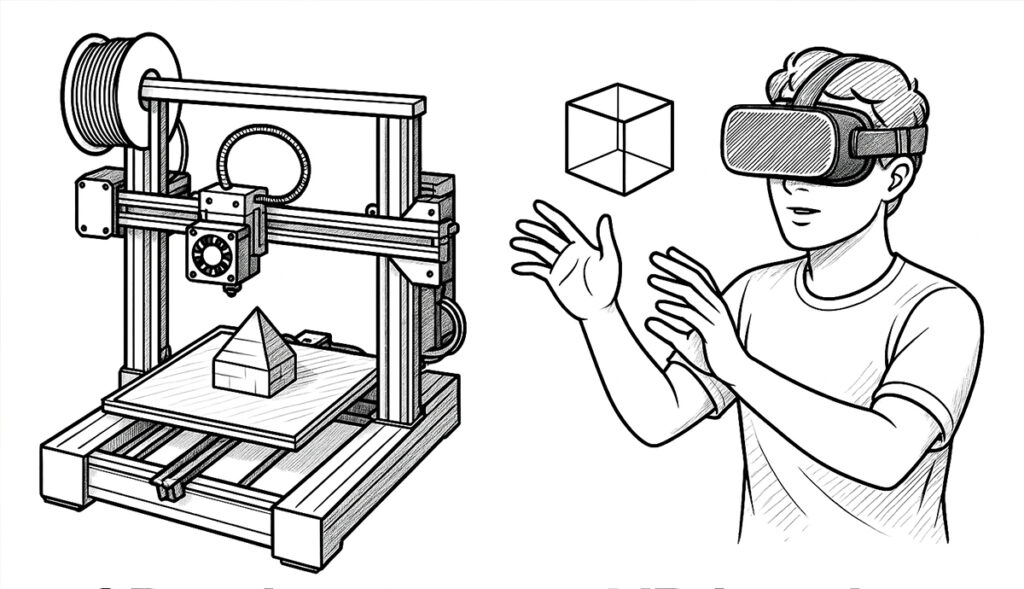

- Fig. 1.1 shows two emerging technologies.

Discuss how emerging technologies have impacted the manufacture of products used in society.

Your answer should:

- include examples of emerging technologies

- evaluate the impact of the emerging technologies on the manufacture of products

- discuss the impact of emerging technologies on the wider issues in design and technology (including cultural, economic, environmental and social factors).