High school Design and Technology students often need to test and evaluate products. This may involve devising and applying appropriate tests as necessary to assess the success of a product against original specifications or design need. This article provides an introduction to destructive and non-destructive testing methods.

Products are tested for many reasons. Testing helps designers understand whether a product can cope with stressful situations during use, shipping, storage, and even during construction. Testing can help designers ensure products have a reasonable life span, are safe for users, and are popular and desirable, meeting the design specification. In short, testing helps us identify strengths and weaknesses of a product, and identify areas for modification and improvement.

Testing methods can be separated into two groups: non-destructive and destructive.

What is non-destructive testing and why is it important?

Non-destructive testing methods examine the quality of a product without permanently altering or destroying it. In other words, non-destructive testing methods allow you to verify the quality of a product without compromising its usability.

Examples of non-destructive testing

- Visual inspection – used to check for print quality, color accuracy, and surface defects. Can be automated using high-resolution cameras and image analysis software. Results are usually compared to specific requirements or standards.

- Observations in use – with the product used in its intended environment where possible (if observation occurs in an artificial environment, so results are less likely to reflect reality).

- Measuring of movement, flaws, joints, and other conditions – often considering issues of ‘tolerance’ (the acceptable range or variation from a specified measurement or condition that still allows a component or structure to function safely and effectively). When inspectors perform non-destructive testing, they often check whether these variations fall within the predetermined acceptable tolerance ranges. If a measurement exceeds the tolerance limits, it indicates that corrective action may be needed. For example a movement in a joint might be acceptable within a specific range (perhaps ±5mm) before it indicates a structural issue.

- Gloss measurement – used to measure the reflective properties of a surface. Important for evaluating the finish of printed materials, coatings, and laminates. Can detect inconsistencies in surface texture or coating application.

- UV fluorescence inspection – Uses ultraviolet light to reveal features not visible under normal lighting conditions. Can detect the presence of optical brighteners in paper or special security inks. Useful for verifying authenticity or checking for inconsistencies in coating applications.

Why are non-destructive tests often used during the manufacture of products?

- Avoids wastage of materials: Non-destructive testing allows manufacturers to check product quality and consistency without sacrificing valuable materials and finished products. Consequently, non-destructive testing can be more commercially viable than destructive testing as it doesn’t involve destroying the product. It is also better for the environment, as it minimises waste.

- Every product can often be tested, rather than just random samples, as there’s no loss of material or finished products. This is particularly the case when this process is automated.

- Improves quality control, ensuring consistency and quality in high-volume production runs, such as by meeting specific industry standards or client requirements. It also means that products can be tested at various points in the supply chain without affecting their final use.

- Continuous monitoring: Non-destructive methods enable testing without interrupting the production process, avoiding bottlenecks or delays. For example, optical scanning systems can continuously monitor print quality on packaging lines, allowing immediate adjustments when issues are detected rather than discovering problems in completed batches. This means issues can be identified before they become critical or result in large amounts of waste.

- Legal compliance: Non-destructive testing can help with regulatory compliance without damaging products. In some industries, testing is needed for certification purposes. These certifications provide legal protection if something subsequently goes wrong or someone is injured.

Disadvantages of non-destructive testing

- Not testing until ‘breakage’ means you are unsure where the limits of use are found

- May involve higher initial costs, requiring specialised equipment (like ultrasonic detectors or X-ray machines)

- May require highly skilled technicians or inspectors with specific certifications

- May involve interpretation errors (unlike testing to failure, which is often much more clear-cut)

What is destructive testing?

Destructive testing involves repeatedly subjecting a product to harsh or extreme conditions until it fails or breaks.

Although it is called “destructive” testing, these methods don’t always result in the complete destruction of the product. Sometimes, the test is stopped at a certain point of stress or deformation, which might not fully destroy the item but render it unusable for its intended purpose. Although these methods don’t always result in the complete destruction of the product, they do push the design to its limit, often in ways that damage the product.

This type of testing helps to determine the limitations of a product and understand structural performance under various stressors, improving durability, usability, and effectiveness.

Examples of destructive testing

- Abrasion tests – simulating wear and tear that occurs during normal use, handling, or transportation. Subjects the item to repeated rubbing or scraping, evaluating the durability of structural and decorative elements under various handling conditions. These tests help determine the durability and longevity of various surfaces. Might involve the friction between two surfaces rubbing against each other – such as a weighted arm with the test material that rubs back and forth across the sample, or with abrasive wheels rotating across a test surface until failure occurs.

- Fade resistance tests – seeing how colours and coatings fade over time when exposed to an outdoor environment. Exposes the item to intense light (often UV) to simulate long-term exposure.

- Chemical resistance tests – ensuring the longevity of various elements when subjected to various chemical conditions.

- Drop testing – whereby packages are dropped from various heights and angles to simulate shipping and handling conditions. This tests both the structural integrity of the package and the ability of the graphics to withstand impact without peeling or damage.

- Crush testing – this applies pressure to the product to simulate stacking during storage or transportation. Evaluates how well the package maintains its shape and protects its contents, as well as how the graphics hold up under pressure.

- Vibration testing – simulates the vibrations experienced during transportation. Might be used to see if the product will break during transit.

- Moisture resistance testing – exposes a product to high humidity or direct water contact. Assesses how well the material and printed graphics resist water damage, warping, or ink bleeding.

- Tear resistance testing – measures the force required to propagate a tear in the material. Important for both the structural integrity and the preservation of high quality surfaces and so on.

- Burst strength testing – applies increasing pressure until a package bursts.

Why do manufacturers carry out destructive testing of materials?

- To determine expected lifespan: Destructive testing helps predict how materials will age and degrade over time. For example, UV exposure testing is conducted until failure to determine how long outdoor signage materials will maintain their structural integrity and visual properties.

- Safety compliance: Manufacturers must ensure their materials meet strict safety standards through rigorous testing. For example, packaging materials for hazardous goods are subjected to impact and stress testing until failure to determine their maximum safety threshold in real-world conditions.

- Consistent quality control: Destructive testing allows manufacturers to verify the consistent quality of materials across different batches.

- Performance under extreme conditions: Materials need to be tested beyond their normal operating conditions to understand their failure points. Failures can provide valuable information for the design team, allowing them to see precisely where a structure or element failed. New materials must be thoroughly tested to understand their limitations. For instance, biodegradable packaging materials undergo accelerated breakdown testing to determine their exact decomposition timeline.

- Cost-benefit analysis: Different materials have different properties and so these need to be compared to find the best fit for the circumstance (fitness for purpose), balancing performance with cost, and other variables, such as aesthetics and impact on the environment. Destructive testing helps manufacturers determine the most cost-effective materials for specific applications, avoiding over-engineering and unnecessary expense.

- Environmental impact assessment: Materials can be tested to understand their breakdown characteristics and environmental impact. Recyclable materials undergo degradation testing to determine how they will perform during the recycling process and to ensure they meet environmental standards.

- Legal protection: Manufacturers need to establish product limitations to protect against warranty claims and liability issues. Standardized destructive testing provides verifiable data about material properties and performance limits that can be used for industry certifications. Destructive testing clearly shows the limits of performance – the point at which a product will fail or become unusable, unlike non-destructive testing, which may not provide such a clear-cut data. For example, point-of-sale displays and temporary structures are tested to failure to determine safe load limits and expected lifespan under normal use conditions.

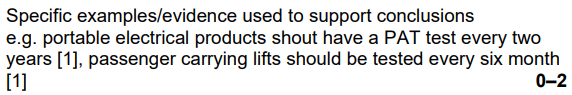

Example: In the UK, portable electrical products should have a PAT test (Portable Appliance Testing every two years, to confirm they are safe to use.

- Resilience during shipping: Understanding material failure points helps manufacturers plan for transportation and storage conditions. Packaging materials are tested to determine their stacking strength limits and crush resistance to ensure they survive the distribution process.

Disadvantages of destructive testing

- More expensive – as whole product is ruined

- Worse for the environment – as wastes materials

- More disruptive to production – unlike non-destructive testing – may require dedicated production runs just for test specimens

- Because only sample products are destroyed, these may not be good representatives of the whole batch

- Once destroyed, you can’t complete follow-up tests on the same specimen

- Unsuitable for in-service testing (monitoring a product while in use)

Products can be tested at many stages:

Early in design process:

- Drawings or conceptual models shown to clients to establish whether design is on the right track – initial feedback;

- Surveys undertaken.

Towards the end of the design process:

- A functioning prototype or digital model can be tested;

- Advantageous to test a prototype, as opposed to discovering a product doesn’t work after you have manufactured a lot of them.

After completion:

- Tests taken at this stage ensure product is safe and functions as intended;

- Might involve product certification = quality assurance, measuring product against nationally accredited test standards (i.e. the Building Code), where the product must meet minimum requirements.

While in use:

- To establish whether the product copes with ongoing stresses over time;

- To identify areas for improvement of future products;

- Maintenance testing – checking if it meets specific standards or needs maintenance while in use

Devising your own testing methods

Students often have to devise and apply a range of appropriate tests to assess the performance of a product against its specifications or intended use. These should be specific to the product in question and relate closely to the intended function of the product.

It is helpful to photograph these tests, providing evidence of primary research, using the data draw conclusions, making justified comments about strengths and weaknesses.

Note: In addition to the destructive and non-destructive testing methods described here, this testing and evaluation process may involve conducting market research, gathering data via questionnaires, interviews, and so on.

Sample examination questions (AS Design & Technology)

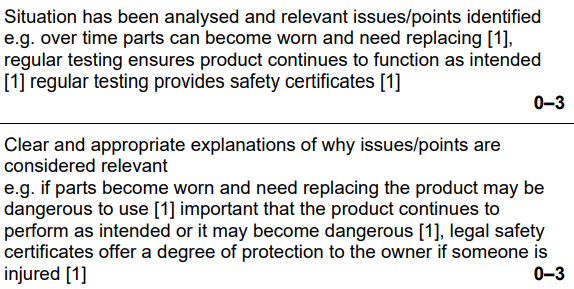

Discuss why products, such as a hydraulic lifting device, are tested at regular intervals.

Examiner comment: Candidates often had a good understanding of why designers test products such as the hydraulic lifting device at regular intervals. The health and safety of those using the device was the most popular response.